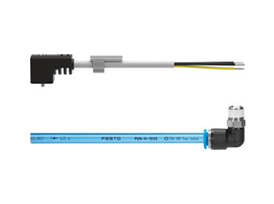

FESTO (Festo) Brand and MSFG - 24/42 - 50/60 Solenoid Introduction

FESTO (Festo) is a company with significant influence in the global field of automation technology, renowned for its high-quality, innovative products, and outstanding service. For many years, the company has been committed to providing comprehensive solutions for industrial automation, with its products widely used in various industries such as automotive, electronics, food and beverage, packaging, and more.

The MSFG - 24/42 - 50/60 solenoid is an important product under the FESTO brand. This solenoid plays a key role in Festo's solenoid valve system, capable of converting electrical energy into magnetic energy, thereby driving the valve core action of the solenoid valve to achieve precise control of gases or liquids. The numbers in its model have specific meanings, with '24/42' possibly representing certain electrical parameters such as rated voltage, and '50/60' likely related to frequency, indicating that the solenoid can be used in power environments of 50Hz or 60Hz, giving it a broader applicability.

Features and Advantages of FESTO (Festo) Solenoid MSFG - 24/42 - 50/60

Firstly, in terms of performance, the MSFG - 24/42 - 50/60 solenoid has an excellent response speed. It can achieve the conversion from electrical energy to magnetic energy in a short time, thereby quickly driving the solenoid valve core action, greatly improving the efficiency of the system. For example, in some automated production lines with high response time requirements, this solenoid can ensure that the solenoid valve is opened or closed in a timely manner, ensuring the continuity and stability of the production process.

Secondly, the solenoid has good stability and reliability. Festo uses advanced production processes and high-quality materials to manufacture this solenoid, allowing it to function normally in various harsh industrial environments. Whether it is high temperatures, humidity, or strong electromagnetic interference, the MSFG - 24/42 - 50/60 solenoid can maintain stable performance, reducing the probability of failures and lowering maintenance costs for businesses.

Furthermore, from an energy-saving perspective, this solenoid has low power consumption. It uses optimized electromagnetic design to achieve efficient driving while effectively reducing the consumption of electrical energy. For some automated systems that run for long periods, this means significant savings in energy costs, meeting the modern industry's requirements for energy conservation and emission reduction.

Additionally, the MSFG - 24/42 - 50/60 solenoid also has good compatibility. It can match various types of Festo solenoid valves, making it convenient for businesses to integrate and upgrade systems according to their needs. At the same time, its standardized design also makes installation and maintenance easier, reducing the installation and debugging time and difficulty for businesses.

Application Areas and Market Prospects of FESTO (Festo) Solenoid MSFG - 24/42 - 50/60

In the automotive manufacturing...

Coil MSFG-24/42-50/60 belongs to the Connection Technology series under FESTO company, model number MSFG-24/42-50/60. To purchase or inquire about Coil MSFG-24/42-50/60, you can directly contact 158 0047 0089 (Mr. He).