When using the CMK2-CC-20-12 pressure reducing valve, it is essential to pay attention to the selection. Improper selection can cause water blocking and air leakage. When selecting a hydraulic control valve, the hourly steam consumption of the equipment must be multiplied by a selection multiple of 2-3 times to determine the condensate water volume, which is used to select the排水量 of the hydraulic control valve. This ensures that the hydraulic control valve can quickly discharge the condensate water when starting up, rapidly increasing the temperature of the heating equipment. Insufficient discharge capacity of the hydraulic control valve can lead to condensate water not being discharged in a timely manner, reducing the thermal efficiency of the heating equipment. The nominal pressure of the timer has different levels such as 0.6, 1.0, 1.6, 2.5, and 4.0MPa. The working pressure of the medium transported by the pipeline should be less than the nominal pressure value of the valve. The cylinder self-locking function processing steps, the unit maintains the operating state, single valve operation mode, the load is limited to 220MW or less, close the oil admission cut-off valve of the #4 high-pressure gate oil drive, cut off the oil circuit. Remove the connecting pin between the oil drive and the lever arm of the cylinder, first support the lever arm with a jack, and insert an appropriate spacer block (square steel) into the gap under the accumulator spring. DFM-12-80-P-A-GF, pressure reducing valve LR-M1-N1/8-07GIKLFR-D-MIDI-A, AEVULQ-20-20-A-P-A-S206 pressure reducing valve LR-M2-N3/8-07, DSBC-50-320-PPVA-N3, MPPE-3-1/2-10-420-B, polyurethane air tube PUN-10X1,5-SI double-acting anti-twist cylinder DZH-16-40-PPV-A, pressure reducing valve LR-M2-G3/8-04GKEMME-AS-80-M-HS-AMB, AEVULQ-25-30-A-P-A-S6 series lockable pressure reducing valve LRS-1/2-D-7-I-MIDI, DSBC-50-250-PPSA-N3AEVULQZ-16-15-A-P-A, DGC-50-600-G-PPV-ADSM-16-270-CC-FW-A-B, D series pressure reducing valve LR-1/4-D-I-MIDI air tube PUN-12X2-S-2-BL, GRLA-M3 pressure reducing valve LR-M3-N3/8-10GK, DSBC-50-125-PPVA-N3, DSBC-50-125-PPSA-N3AEVULQ-100-60-A-P-A-S6, DGC-K-40-200-PPV-A-GK, DSBC-32-320-PPSA-N3, pressure reducing valve LR-M2-N1/4-10 polyurethane air tube PUN-6X1-DUO-BS, VN-05-N-T3-PI4-VI4-RI4 pressure reducing plate ILR-03-ZP-A-7,0, DSBC-50-200-PPVA-N3, 193144 GRLA-1/8-QS-6-D, DFM-32-125-P-A-KFDSBC-63-250-PPVA-N3, CLR-40-10-R-P-ADGC-18-6

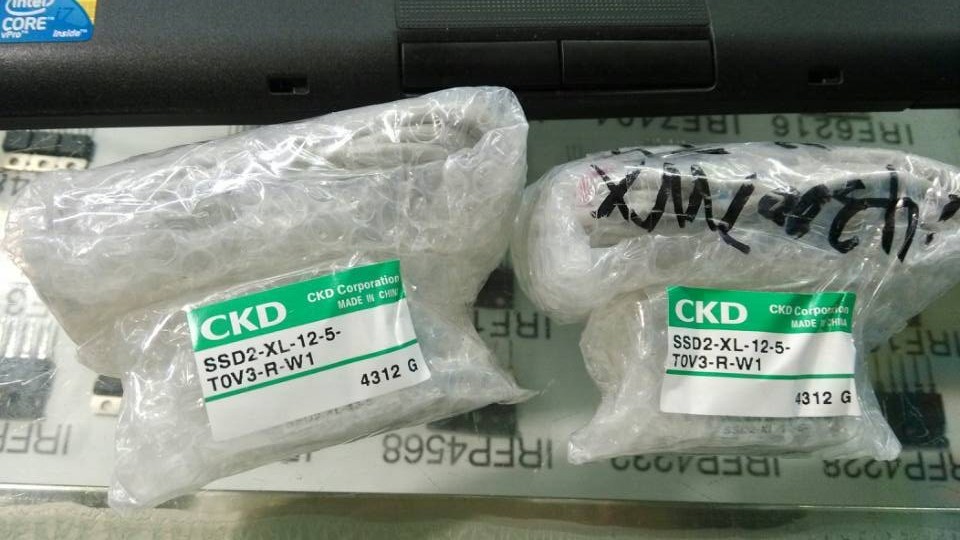

Double acting cylinder CMK2-CC-20-12 belongs to the Air Pressure Cylinders series under CKD company, model number CMK2-CC-20-12. To purchase or inquire about Double acting cylinder CMK2-CC-20-12, you can directly contact 158 0047 0089 (Mr. He).