In the CMK2-G-FA-32-75 four-wire sensor, the two wires with the highest resistance are the excitation end (input end), and the other two wires are the signal output end. After determining the excitation and signal lines, the resistance between any excitation line and signal line should be equal. If the resistance difference between any excitation line and the two signal lines is greater than 2Ω, the sensor is generally considered to be no longer usable and is usually judged to be damaged. (In cases where the resistance difference is greater than 1Ω, sometimes it can be adjusted by compensating the zero point, which is an exception to special cases.) Sensors that have been subjected to chemical corrosion, electric shock, lightning strikes, or mechanical damage will generally not meet the above characteristics when measuring. The adhesive used for bonding the sensor resistance strain gauge mainly adopts two-component polymer epoxy series adhesives. The performance of polymer chemical products is closely related to various physical and chemical indicators of each component, such as purity, structure and size of the molecular chain, storage time, ratio of components, molecular modification, mixing method, mixing curing time, curing time, curing temperature, additives and percentage, etc. Pressure reducing valve LR-M3-N3/8-10G, pressure reducing valve LR-M2-N1/4-04K vacuum suction cup ESV-100-SF, vacuum suction cup ESV-20-SFDGC-12-200-G-P-A, DGC-K-80-1800-PPV-A-GK, D series pressure reducing valve LR-1/2-D-O-I-MIDI, pressure reducing valve LR-M3-N1/2-10IVN-05-N-T3-PQ2-VQ2-RQ2, pressure reducing valve LR-M1-G1/8-10KDSBC-40-300-PPSA-N3, DSBC-40-30-PPSA-N3 polyurethane air tube PUN-6X1-SW, DGC-32-250-G-PPV-A pressure reducing plate LR-ZP-A-D-3, D series pressure reducing valve LR-1/4-D-O-I-MIDIGRLA-M5-QS-6-D, GRLA-1/8-QS-3-RS-DDSBC-63-160-D3-PPVA-N3, DSBC-50-70-PPVA-N3, air tube PUN-12X2-S-2-SW, polyurethane air tube PUN-E-12X1,6-BL-200 pressure reducing valve LR-M1-G1/8-07GIK, pressure reducing valve LR-M2-G1/4-07GAEVULQZ-50-15-A-P-A, AEVULQZ-25-5-A-P-A12 547596 DSM-12-270-FW-A-B, DSBC-32-150-D3-PPSA-N3EMME-AS-100-M-HS-ASB, air tube PUN-6X1-S-1-SW pressure regulating valve LR-ZP-A/B-D-2, pressure reducing valve LR-M3-G3/4-10GIKAEVULQZ-40-50-A-P-A-S6, DFM-20-80-P-A-GF double-acting anti-torsion air cylinder DZH-20-160-PPV-A, air tube PUN-6X1-S

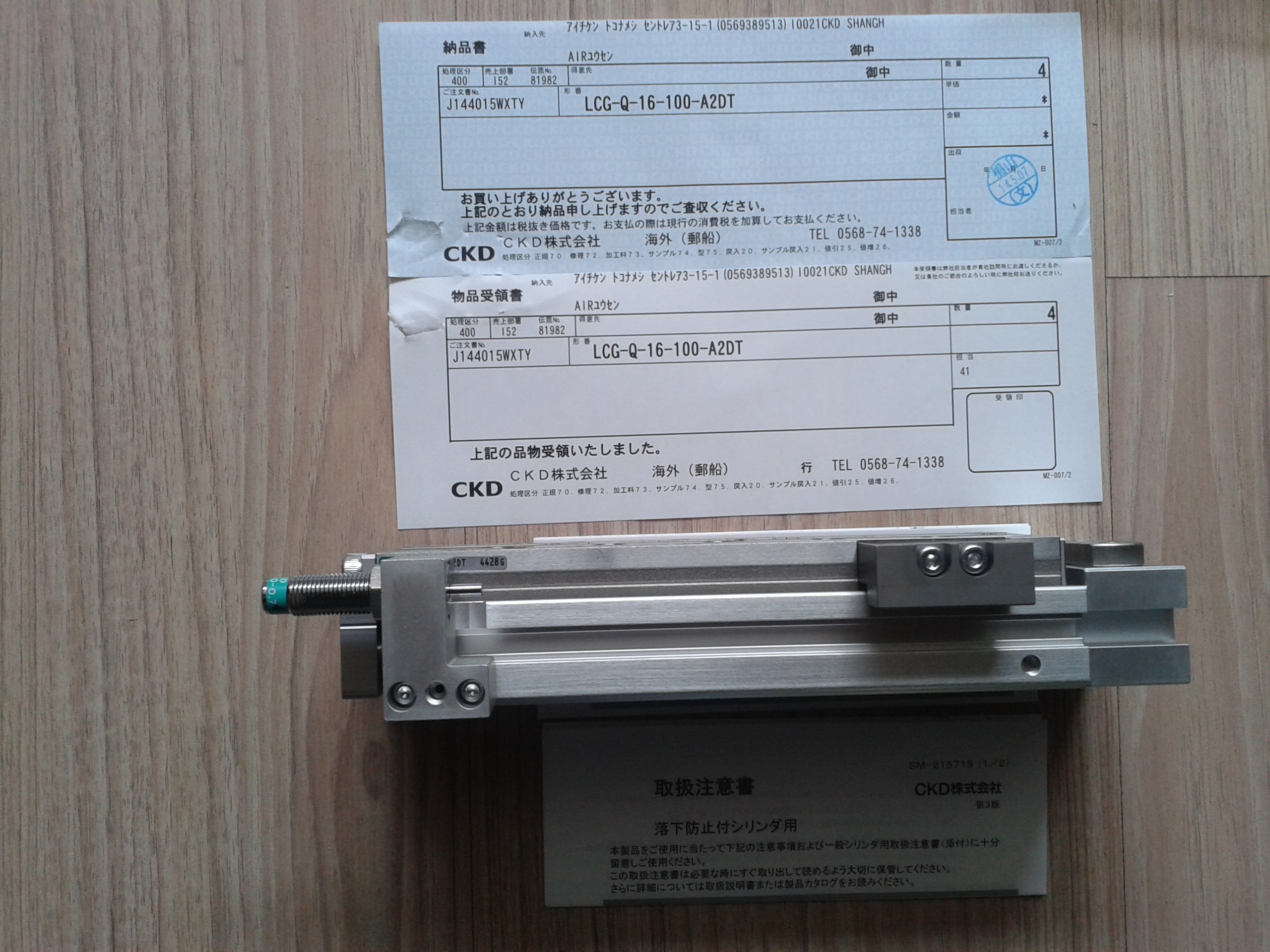

Double acting cylinder CMK2-G-FA-32-75 belongs to the Air Pressure Cylinders series under CKD company, model number CMK2-G-FA-32-75. To purchase or inquire about Double acting cylinder CMK2-G-FA-32-75, you can directly contact 158 0047 0089 (Mr. He).