The festo directional cylinder DFM-50-200-P-A-KF utilizes ion beam sputtering coating technology to deposit an insulating film and alloy resistance material onto a metal elastomer with good high-temperature performance. After photolithography and etching, the grid strain resistance is formed, converting the measured pressure into deformation of the elastomer, which in turn causes changes in the resistance value of the alloy thin film strain resistance. By forming a Wheatstone bridge, an electrical signal proportional to the pressure is obtained. 1. Corrosive media: Plastic King cylinders and all stainless steel are recommended; for strongly corrosive media, an isolated diaphragm type must be used. Neutral media also favors cylinders with copper alloy valve housing materials; otherwise, rust flakes often fall off from the valve housing, especially in infrequently operated situations. Ammonia valves should not use copper materials. Soft start valves are suitable for equipment or pipelines with a working temperature ≤200°C, unstable back pressure, or toxic, corrosive media, serving as an overpressure protection device. The connection flange standard ≤4MPa adopts the JB/T6...94 series 1. >4MPa adopts the JB/T...94 series 2 standard. Full-lift safety valves are suitable for aircraft equipment or pipeline systems with variable back pressure and toxic, flammable media, serving as a safety protection device. The bellows area effectively protects springs and other parts from corrosion, extending the product's service life. The bellows balanced safety valve is a type of overpressure protection device for pressure pipes and containers with toxic, harmful, and flammable media, using stainless steel formed bellows to ensure zero external leakage of the medium, and also to balance the back pressure of the safety valve outlet, ensuring the accuracy of the set pressure. Before closing the vent pipe of the high-pressure safety valve, pressurize the vent pipe from the pressure measuring valve, slowly increase the pressure until gas is discharged from the vent, and check whether the pressure gauge reading at this time matches the set value, which should be repeated three times. The slight vibration of the cylinder cover; this slight vibration causes the rodless cylinder cover seal maintenance pack to undergo relaxation and compression, thereby accelerating the damage to the rodless cylinder cover seal maintenance pack and affecting its sealing performance. Factors to consider when selecting solenoid valves; after identifying the cause of the solenoid valve, propose a solution: in the PLC program, extend the motor vibration time, try to震荡 out all the material before closing the valve; adjust the zero point of the weighing instrument, only when all the material is out does it display zero, at which point the PLC sends the signal to close the valve; replace the solenoid valve with a double eccentric elastic hard-sealed solenoid valve (or use a centerline sealed rubber butterfly valve, considering that there are occasionally large particles in the material, rubber sealing may not be durable). If the solenoid valve is for fine powder without particles, a soft-sealed butterfly valve can be considered, because the valve seat of the solenoid valve is an oblique sealing surface, which is a surface seal, so the material easily accumulates on the sealing surface and cannot be discharged quickly. Single偏心 or solenoid valves do not have this disadvantage; even if there is a little material on the sealing surface, it is scraped off by the valve plate when the solenoid valve is closed, thus ensuring good sealing and durable sealing surfaces. After such modifications, this problem has never occurred again. Solenoid valves have a simple structure, small size, light weight, and are composed of only a few parts. They can be quickly opened and closed by rotating 90 degrees, and are easy to operate. At the same time, the valve has good fluid control.

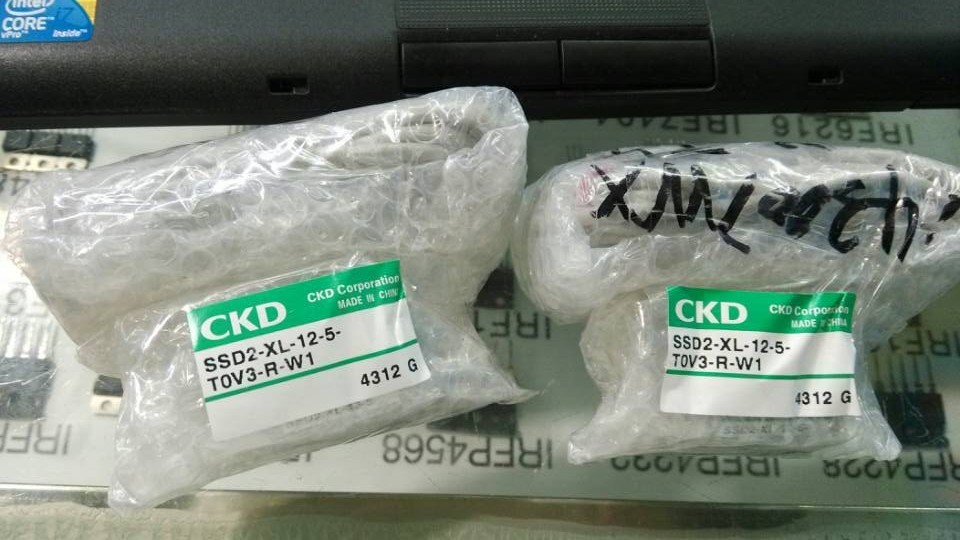

Guided Cylinder DFM-50-200-P-A-KF belongs to the Air Pressure Cylinders series under CKD company, model number DFM-50-200-P-A-KF. To purchase or inquire about Guided Cylinder DFM-50-200-P-A-KF, you can directly contact 158 0047 0089 (Mr. He).