When selecting the appropriate IMI NORGREN pneumatic components, consider the following factors:

Application Needs: Understand the specific working environment and tasks, such as load, speed, and stroke.

Air Source Conditions: Ensure that the air source pressure and flow meet the component requirements.

Installation Space: Confirm available space and select components of suitable dimensions.

Environmental Factors: Consider the working environment’s temperature, humidity, and potential corrosiveness to choose suitable materials and designs.

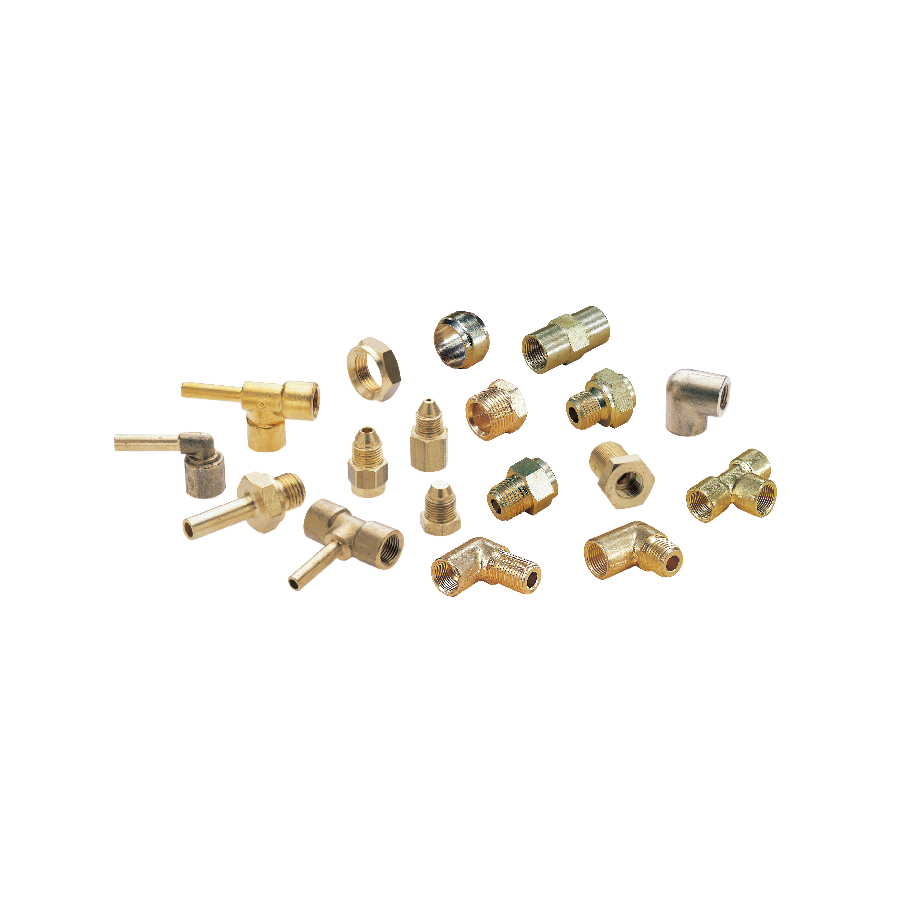

![IMI NORGREN Fittings & Tubes | Pneumatic Connectors UK Supplier[8] IMI NORGREN Fittings & Tubes | Pneumatic Connectors UK Supplier[8]](https://cdn6.zhuocms.com/storage/smcgoodscom/pages/202504/0967f67cf02d5dd.png)