The SCA2-CB-63B-200-T0H-D-YB1 cylinder valve core's copper nut and ductile iron frame are tightly connected as one using a special process, ensuring that they will not loosen under long-term operation and water flow impact, thus preventing valve control failure. The solenoid valve's exhaust flows to the manifold exhaust port, and since there is a silencer installed on the manifold exhaust port, this silencer is always leaking. ... Because the manifold is a pneumatic component for centralized control of the intake and exhaust of multiple pneumatic actuators, more than 2... When installing coarse flat or pleated filters, the galvanized mesh surface should be oriented towards the back of the air outlet. When installing bag filters, the length of the filter bag should be vertical to the ground, not parallel to the ground; if the valve core is already damaged and the rodless cylinder has been used for too long and is damaged, in this case, the new solenoid valve should be replaced directly. AB41-4A-COIL-AC220V/Z, GWS12-0/KAB41-03-3-C4A-AC220V/Z, GWL12-0/KB2019-2C, GWT12-0/KFSM2-NVF101-S081B, GWS12-10/KGFGB31-3-0-12C-3, SCS2-LN-T-160/ZG39D-6-P04, CVSE2-25A-05-02HS-1VNA-40-AC100V, P5142-M6B-DC24VSRL3-LB1-32B-680/T, HH 8×5/K116B-501JM, 6632A-000-PM-113JD116B-591BA M0D:0389, 52A-11-A0A-DM-DDAA-1BA116B-610JM, 225B-661BAAA116B-611BAAA, MV-B2A-AABA-DM-DDAJ-1JJ M0D5889116B-611JB, 250B-501JJ M0D8486116B-871JM, 130B-501JJ M0D8486117B-111BA, 6211C-000-PM-501DA117B-121BA, BV310A-LD1-00-BHBA-BTA117B-121JC, 93A-000-EJG130B-111JJ, PME-DABE130B-111JJ M0D:0458, 56C-63-611JB130B-121JB, 52A-31-D0A-DM-DJAA-1BA161B-501JB, DMB-DFFJ-1JM-1161B-611JD, 36A-B00-JDA0-1KA166B-611JM, 111B-501BAAA166B-612JB, 16375. All information provided by Shanghai Jugu Pneumatic Equipment Co., Ltd., unauthorized use is prohibited. For more information, please contact the following customer service.

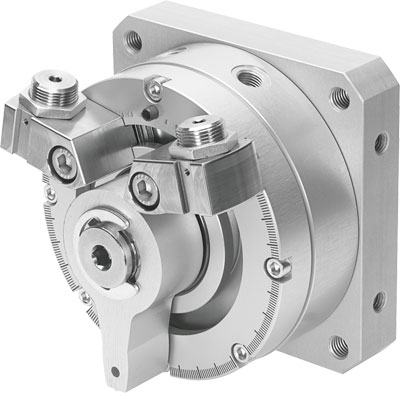

Medium Cylinder SCA2-CB-63B-200-T0H-D-YB1 belongs to the Air Pressure Cylinders series under CKD company, model number SCA2-CB-63B-200-T0H-D-YB1. To purchase or inquire about Medium Cylinder SCA2-CB-63B-200-T0H-D-YB1, you can directly contact 158 0047 0089 (Mr. He).