Understanding the selection principle of SCA2-T-63 cylinders; once the cylinder is in the open position, there is no longer contact between its valve seat and valve disc sealing surfaces, thus the mechanical wear on its sealing surfaces is relatively small. Since the valve seat and valve disc of most electrically operated shut-off valves are relatively easy to repair or replace sealing elements without needing to remove the entire valve from the pipeline, this is particularly suitable for situations where the valve and pipeline are welded together. When replacing the packing of the blocking cylinder, the old packing must be removed, but care must be taken not to damage the valve stem, sealing disc, and packing box. After all the old packing has been cleared, new packing can be installed. When installing new packing, first choose packing that meets the size and performance requirements; do not substitute high for low, large for small, or flatten for use. Then the packing should be cut into single rings, with the joints of the packing neatly cut into sharp angles, and the length should be appropriate. When cutting the packing, it can be tightly wrapped around a rod with a diameter equal to the valve stem diameter, marked with the cut line, and then cut. The cut packing rings should be added one by one to the packing box, and each ring should be pressed and compacted with a gland or special tool, with the cut ends of each single piece of packing staggered. PR92B-KAAA, N-35002PR92B-KEAA, 45A-BC1-DDAJ-1KA45A-AA1-DDFJ-1KA M0D:CLSF, 45A-SC1-DDAJ-1KD45A-AC1-DDFJ-1KA M0D:CLSF, 916B-PM-501BA57D-23-502JA, 57D-76-111JA82A-AF-CAA-TU-DAA3-1DK M0D:532B, S-63002CPR92C-KAAA, 6341D-351-PM-501DA56C-17-501JA, 411A-D0A-DM-DDAJ-1KA45A-AA1-DDFA-1BA, 6331D-351-PM-591DA45A-AC1-DDAJ-1JM, 46A-AC1-JDAA-1GADMB-DDAJ-1KA, 414A-D0B-DM-DDAJ-1KJ16433, 434A-D0B-DM-DDAJ-1KJ36A-B00-JDE0-1KJ, 92B-AAA-000-DM-DDAP-1DM M0D:532B33A-AAB-RDBA-1BA, 92B-EAA-000-DM-DDAP-1DM M0D:532B34B-ABA-GDAA-1KV, 45A-GC1-DAAA-1BA116B-122JD, E-92050-01-02434B-L00-GFG0-1KJ, E-92050-02-024111B-131BA, 451A-D0A-DM-DDAJ-1JB250B-111BAAA, 55B-14-PI-111JJ35A-AAB-DDAA-1BA M0D:R025, 45A-GC1-

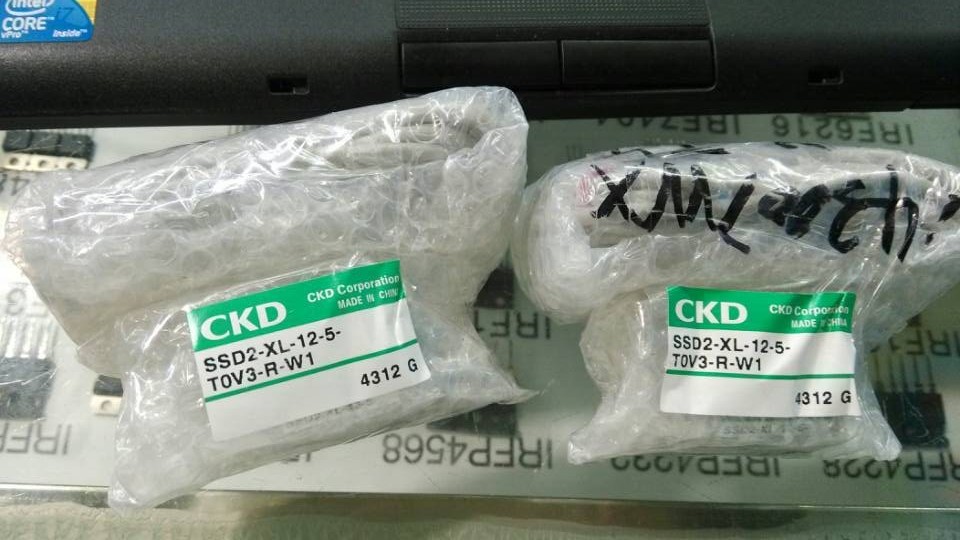

Medium-sized cylinder SCA2-T-63 belongs to the Air Pressure Cylinders series under CKD company, model number SCA2-T-63. To purchase or inquire about Medium-sized cylinder SCA2-T-63, you can directly contact 158 0047 0089 (Mr. He).