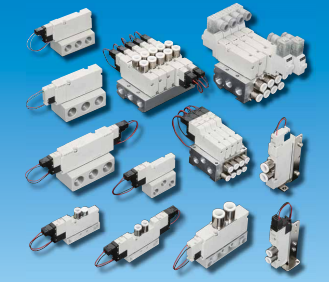

Preceding solenoid valve 4GA219-C6-E2C-3, CKD Seka is a major product of Japan, which includes automation machinery goods applied in backlight tube manufacturing systems, 3D solder paste printing inspection machines, and automatic drug packaging systems. In the category of component products, there are refined system components, fluid control components, labor-saving components, pneumatic components, including integrated process gas supply systems (IGS), vacuum proportional control systems, drug valves, direct-acting two/three-way valves, coolant valves, medical analysis valves, direct-drive motors, intermittent rotary workbenches, guided cylinders, cylinders, rodless cylinders, electric cylinders, pneumatic three/five-way valves, serial transmission control valves, clean room F.R., F.R.L components, flow sensors, digital electronic control proportional pressure reducing valves, air dryers, precision components, etc. In addition to providing a variety of standard pneumatic products, CKD also customizes products for customers to meet their needs for special solutions. In advanced industries such as semiconductors and liquid crystals, where control equipment is required to be used in ultra-pure environments, drug control components, process gas control components, high vacuum control components, etc., from the gas supply system to the exhaust system related to chip manufacturing, we continuously challenge ourselves to ensure high purity and accuracy for our customers. One of the important pillars of CKD's technological field in Japan is the ability to control and flexibly use units and systems for liquids such as water, air, gas, steam, and oil. Not only various valves and unit system components, but also green sprinkling systems and dust removal control systems, gas combustion systems, various cleaning devices, and water treatment systems, etc., the fields we can engage in research and development are infinitely broad. High quality and colorful styles are the concepts of liquid control equipment. Based on the theme of automation development and manufacturing over the years, 'higher precision, faster, and lower cost', along with unique perspectives and technical strength, we have created this demand-close product. A rich variety of products such as rotary workbenches, direct-drive motors, transfer work units, etc., meet various conditions such as controllability, output, rigidity, high-speed performance, and perfection in the most suitable form. In response to the diverse needs of flow control cleanliness, environmental protection, energy conservation, and more, a wide range of products have been launched. In the development and manufacturing of clean systems and pneumatic auxiliary components centered around 'F.R.L units' and 'air dryers', we fully utilize relevant rich practical achievements and technical expertise to continuously expand the system peripheral equipment. Pneumatic control components such as electric control proportional pressure reducing valves and open serial corresponding valves that control air flow, as well as drive components such as cylinders and electric cylinders that can achieve automation simply and at low cost, are also constantly being enriched. In the future, we will also continue to challenge product development that fully meets market demands as pioneers in pneumatic technology.

CKD Seka solenoid valve models are as follows:

CKD Seka solenoid valve 3GA119-C6-E2-3

CKD Seka solenoid valve 3GA119-M5-E20H-3

CKD Seka solenoid valve 3GA119-M5-E2H-3

CKD Seka solenoid valve 3GA2111-06

Pilot solenoid valve 4GA219-C6-E2C-3 belongs to the Electric Actuators series under CKD company, model number 4GA219-C6-E2C-3. To purchase or inquire about Pilot solenoid valve 4GA219-C6-E2C-3, you can directly contact 158 0047 0089 (Mr. He).