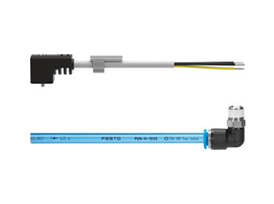

FESTO (Festo) Plug B - 1/2 Introduction

FESTO (Festo), as a globally renowned supplier of automation technology, is known for its products that are characterized by high quality, innovative design, and superior performance. The Festo plug B - 1/2 is a representative product of the brand. This plug has a specification of B - 1/2, where “1/2” typically represents its pipe diameter size, which is common in industrial piping systems and can fit many related pipes and equipment.

The Festo plug B - 1/2 is mainly used to seal pipe ports, preventing the leakage of fluids (such as gases, liquids, etc.), ensuring the sealing and safety of the piping system. It is widely used in various fields such as automated production lines, pneumatic control systems, hydraulic systems, and is an indispensable component for ensuring the normal operation of the system.

From a material perspective, the Festo plug B - 1/2 is generally made of high-quality metal materials, such as stainless steel, brass, etc. These materials have good corrosion resistance, high strength, and wear resistance, capable of adapting to different working environments and operating conditions. For example, in humid and corrosive environments, stainless steel plugs can effectively resist corrosion and extend service life; while in situations where electrical conductivity is required, brass plugs can meet the corresponding needs.

Features and Advantages of FESTO (Festo) Plug B - 1/2

Firstly, in terms of sealing performance, the Festo plug B - 1/2 performs excellently. It adopts advanced sealing design and manufacturing processes, achieving a tight sealing effect and effectively preventing fluid leakage. Its sealing surface is precision machined, with high surface smoothness and excellent fit with the pipe port, even under harsh conditions such as high pressure and high temperature, it can maintain good sealing performance.

Secondly, the plug has good installation convenience. Its structural design is reasonable, with high dimensional accuracy, and it can perfectly fit with standard pipe interfaces. During the installation process, no complex tools and operations are required, just screw or insert the plug into the pipe port according to the correct method to complete the installation, greatly saving installation time and labor costs.

Furthermore, the Festo plug B - 1/2 has high reliability and stability. Due to the use of high-quality materials and advanced manufacturing processes, it can withstand high pressure and impact forces, and is not easily damaged. During long-term use, it can maintain stable performance, reducing system failures and downtime caused by component damage, improving production efficiency and equipment reliability.

In addition, as a well-known brand, Festo has very strict quality control on its products. Each plug B - 1/2 has undergone strict testing and inspection to ensure it meets relevant standards and requirements. This provides users with reliable quality assurance, allowing them to use it with confidence.

Application and Maintenance of FESTO (Festo) Plug B - 1/2

The application range of the Festo plug B - 1/2 is very wide

Plug B-1/2 belongs to the Connection Technology series under FESTO company, model number B-1/2. To purchase or inquire about Plug B-1/2, you can directly contact 158 0047 0089 (Mr. He).