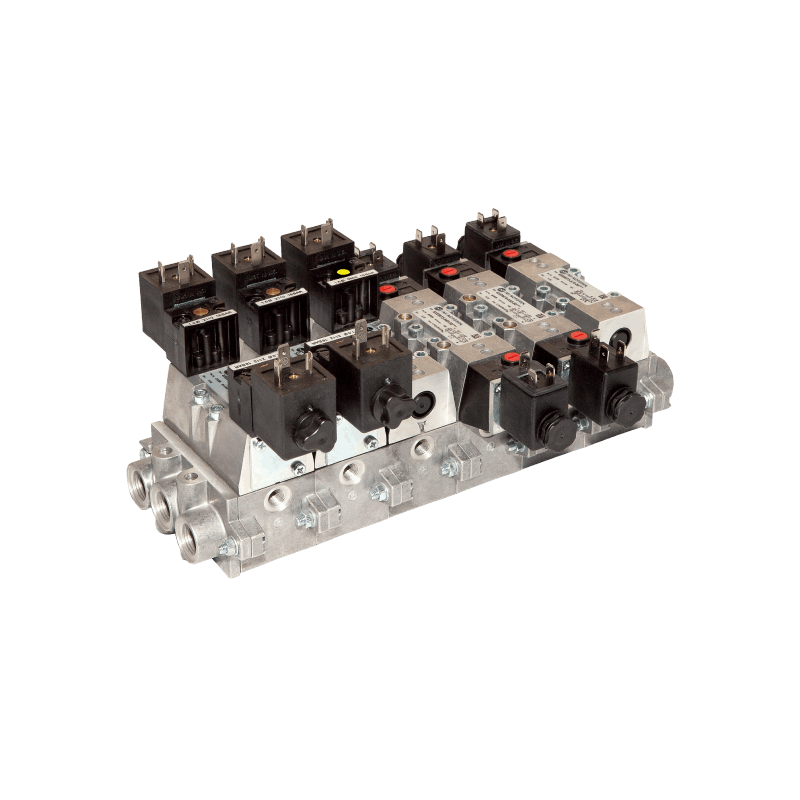

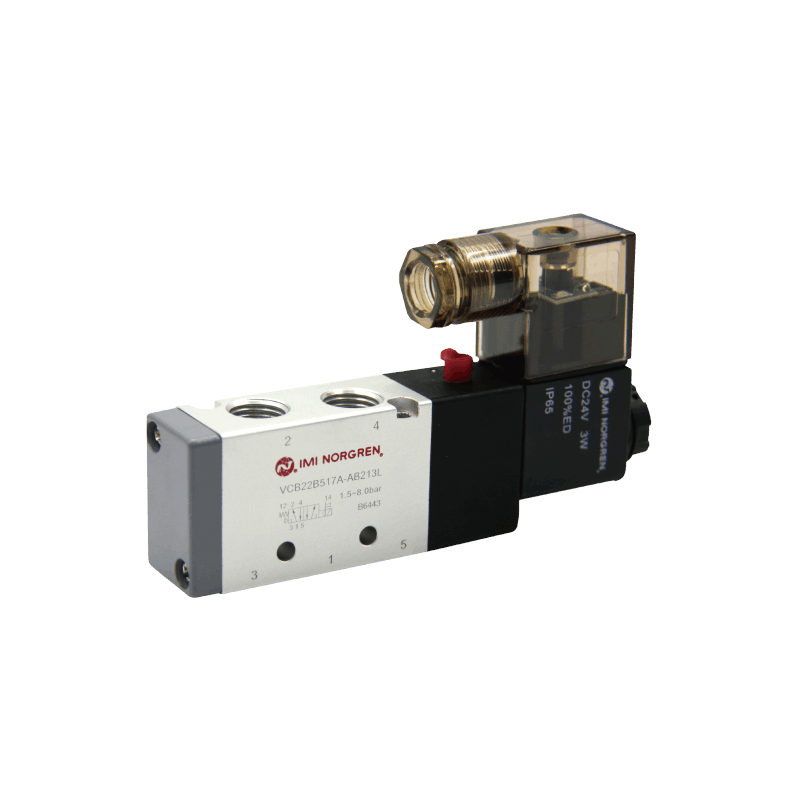

Norgren (IMI Norgren) - Process Fluid and Food Valves - Buschjost Special Valves - 8498390.9100.024.00 Introduction:

8498390.9100.024.00 is a process fluid valve product from the Buschjost special valve range of Norgren (IMI Norgren), a leading manufacturer of process fluid valves. It boasts the following features:

Buschjost special valves are high-performance valves designed specifically for process fluid control, renowned for their exceptional sealing ability, corrosion resistance, and high-pressure tolerance. Manufactured from premium materials, these valves are suitable for demanding industrial environments such as the chemical, pharmaceutical, and energy sectors. With their compact design, rapid response, and precise control over fluid flow and pressure, they also offer long life and low maintenance, ensuring reliability and safety in process operations.

Norgren (IMI Norgren) Company Profile

Norgren (IMI Norgren) is a prestigious brand under the IMI Plc Group, specializing in fluid control and motion control. Established in 1927 and headquartered in the UK, Norgren is a global leader in engineering solutions, offering a wide range of products including pneumatic components, fluid control equipment, filtration systems, valves, and automation components. These are widely used in industrial automation, healthcare, transportation, and energy industries.

Norgren is known for its technological innovation and high quality. Product designs focus on energy efficiency and reliability, meeting the demands of harsh industrial environments. The company has a comprehensive global R&D, manufacturing, and service network, with multiple production bases and branches in Europe, America, and Asia, ensuring rapid response to customer needs.

In the Chinese market, Norgren implements a localization strategy to provide customized solutions, aiding in the upgrading of the manufacturing industry. Core products include cylinders, solenoid valves, pressure reducing valves, and filters, serving key sectors such as automotive, electronics, and food and beverage. Norgren continues to drive intelligence and sustainability, enhancing product performance through digital technology and reducing energy consumption, reflecting a commitment to both environmental protection and efficiency. With a century of technical expertise, Norgren has become one of the leading companies in the fluid control field.

Norgren (IMI Norgren) - Process Fluid and Food Valves - Buschjost Special Valves - 8498390.9100.024.00 Stock and Special Offers

Norgren (IMI Norgren) - Process Fluid and Food Valves - Buschjost Special Valves - 8498390.9100.024.00 may have different price promotions at various times, depending on market conditions. For real-time stock prices and special offers, please contact us for firsthand information. For form inquiries, please leave a message with the consultation content specified as Norgren (IMI Norgren) - Process Fluid and Food Valves - Buschjost Special Valves - 8498390.9100.024.00.

Process Fluids and Food Valves-Buschjost Special Valves-8498390.9100.024.00 belongs to the Valves series under IMI NORGREN company, model number 8498390.9100.024.00. To purchase or inquire about Process Fluids and Food Valves-Buschjost Special Valves-8498390.9100.024.00, you can directly contact 158 0047 0089 (Mr. He).