The festo rotary cylinder DSM-10-240-P-FF is particularly suitable for the production of large-diameter valves. Groove butterfly valves are widely used not only in general industries such as oil, gas, chemical, and water treatment but also in the cooling water systems of thermal power plants. Common types of butterfly valves include wafer-type and flanged butterfly valves. The wafer-type butterfly valve uses double-headed bolts to connect the valve between two pipe flanges, while the flanged butterfly valve has flanges on the valve itself, connecting the valve's flanges at both ends to the pipe flanges with bolts. The strength performance of the valve refers to its ability to withstand the pressure of the medium. Valves are mechanical products that withstand internal pressure, and therefore they must have sufficient strength and rigidity to ensure long-term use without rupture or deformation. II. Allowable shaft end load of servo motor; pressure reducing valves cannot be selected based on the nominal pressure for solenoid valves, as the nominal pressure only indicates the pressure level that the hydraulic control valve body can withstand. The difference between the nominal pressure of the pressure reducing valve and the working pressure is significant. Therefore, the discharge capacity of the hydraulic control valve should be selected based on the working pressure difference. The working pressure difference refers to the difference between the working pressure before the hydraulic control valve and the back pressure at the outlet of the pressure reducing valve. When selecting a pressure reducing valve, it is required to accurately block steam and drain water, have high sensitivity, improve steam utilization, not leak steam, have reliable working performance, high back pressure rate, long service life, and convenient maintenance. Cylinder applicability: Inapplicable equals wasting money and causing trouble. 12. Explosion-proof performance, suitable for working in flammable and explosive environments. Cylinder safety: The working principle of the swivel cylinder selection; the main features and functional description of the CLR linear/rotary clamping cylinder, which is suitable for various types of clamping actions. Through the combination of the linear and oscillating movements of the piston and rod, even workpieces outside the clamping range can be inserted and removed. The cylinder can be selected to swing left or right, in addition, the cylinder with a diameter of ? 40 CLR can also perform linear motion. Clamping fingers: Can be ordered as an accessory, product advantages are diversified, easy to install, practical, simple mechanical system, sturdy structure, long service life, low initial installation and maintenance costs, new product: CLR with dust and welding spatter protection, adjustable swivel direction, compact structure, minimal installation space required, hole type conforms to ISO 21287 standard, therefore, standard accessories such as foot brackets and flange mounting parts can be used, the bearing cover and end cover adopt internal threads, making the cylinder installation simple, whether direct installation or using installation accessories, clamping fingers, including easily installed rubber caps for protecting sensitive surfaces, can be ordered as an accessory, clamping fingers can be freely adjusted within a 360° range, can be repaired with wear parts. 1 Foot bracket mounting part HNA for bearing cover or end cover 13, 2 Flange mounting part FNC for end cover 14, 3 Clamping fingers CLR-...-FS, including clamping fingers, mounted on the output shaft of the air source processing, and a virtual inertia is installed on the regulator side with a conversion value. (Note) Please install the virtual inertia as large as possible within the motor capacity range. (Please use steel with a high specific gravity for the material.) When there are cutting chips and dust attached to the motor and drive, sometimes

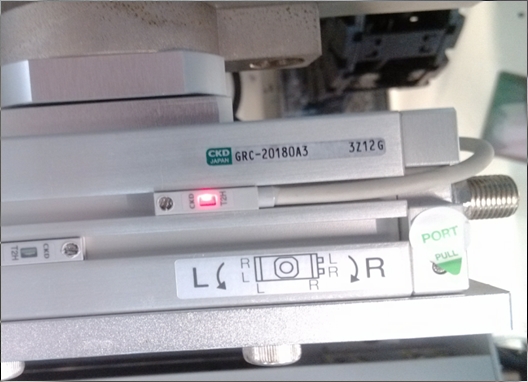

Rotary Oscillating Cylinder DSM-10-240-P-FF belongs to the Air Pressure Cylinders series under CKD company, model number DSM-10-240-P-FF. To purchase or inquire about Rotary Oscillating Cylinder DSM-10-240-P-FF, you can directly contact 158 0047 0089 (Mr. He).