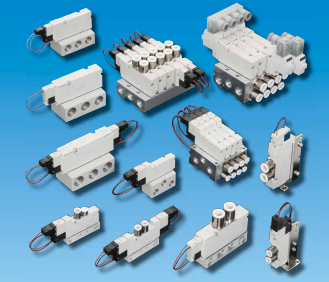

4KB310-10-C2-DC24V solenoid valve CKD in stock, CKD Kikusui, two-position five-way solenoid valve CKD, Shanghai first-tier agent, professional distribution, genuine imported, quality assurance!!CKD related valve products: KD two-way, three-way, four-way, five-way solenoid valves, CKD three-way solenoid valve, CKD pressure-resistant explosion-proof solenoid valve, CKD motor valve, manual switching valve HMV series, HSV series, etc. Product models: 4GD210-C6-E2-3 solenoid valve

4GD430-C10-3DC24V, solenoid valve

4GD119-C4-E2C-3, solenoid valve

4GD129-C4-E2C-3, solenoid valve

4GD219-C6-E2-3, solenoid valve

4KA110-M5-C2P220V, solenoid valve

4KA110-M5-M1BP-DC24V, solenoid valve

4KA121-M5, solenoid valve

4KA210-06-C2-AC110V, solenoid valve

4KB119-00-AC220V, solenoid valve

4KB119-00-B-AC100V, solenoid valve

4KB119-00-B-AC220V, solenoid valve

4KB119-00-D22-DC24V, solenoid valve

4KB219-00DC24V, solenoid valve

4KB219-00DC24V/Z, solenoid valve

4KB219-00/220V, solenoid valve

4KB219-00-24V, solenoid valve

4KB219-00-DC24, solenoid valve

4KB219-00-DC24V, solenoid valve

4KB219-00-M1L-DC24V/Z, solenoid valve

4KB219-06-DC24V, solenoid valve

4KB329-00-D21-AC220V, solenoid valve

4KB429-00-D21-AC220V, solenoid valve

4TB319-00-M1-DC24V, solenoid valve

AB21-02-2-A-DC24V, solenoid valve

AB21-02-3-A-DC24V, solenoid valve

AB21-02-5-DC24V, solenoid valve

AB31-02-1-03A-DC24V, solenoid valve

AB31-02-3-02E-AC220V, solenoid valve

AB31-02-3-AC220V, solenoid valve

AB31-02-3-AC220V

Two-position five-way solenoid valve 4KB310-10-C2-DC24V belongs to the Electric Actuators series under CKD company, model number 4KB310-10-C2-DC24V. To purchase or inquire about Two-position five-way solenoid valve 4KB310-10-C2-DC24V, you can directly contact 158 0047 0089 (Mr. He).