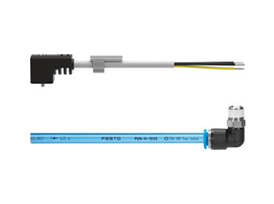

FESTO(Festo)Cable Socket with Cable KMEB - 1 - 24 - 2.5 - LED Introduction

FESTO (Festo), as a globally renowned supplier of automation technology, is known for its products that are characterized by high quality, high performance, and innovative design. The cable socket with cable KMEB - 1 - 24 - 2.5 - LED is one of the many excellent products from Festo. This product has a wide range of applications in the field of industrial automation, providing reliable solutions for the electrical connections of various devices.

In terms of the model, 'KMEB' represents the series name of the product, '1' may indicate a specific version or specification number of the product, '24' usually refers to the applicable voltage being 24V, which is a common voltage level in industrial electrical systems and can be compatible with many devices. '2.5' may be related to parameters such as the cross-sectional area of the cable, an appropriate cable cross-sectional area can ensure good current transmission and stability. And 'LED' indicates that the socket is equipped with a light-emitting diode, a design that not only can visually display the working status of the socket, making it convenient for operators to monitor in real-time, but also can improve the safety of use to some extent.

Features and Advantages of FESTO (Festo) Cable Socket with Cable KMEB - 1 - 24 - 2.5 - LED

Firstly, in terms of quality, Festo has always adhered to strict production standards and quality control systems. KMEB - 1 - 24 - 2.5 - LED is made of high-quality materials, and its socket and cable have good wear resistance, corrosion resistance, and high-temperature resistance. This allows the product to work stably in various harsh industrial environments, greatly extending the service life, reducing downtime and maintenance costs caused by equipment damage.

Secondly, the design of this product pays great attention to the user experience. The connection method of the cable socket is simple and convenient, allowing operators to quickly complete installation and removal, improving work efficiency. At the same time, the design of the LED indicator light enables users to clearly understand the power status of the socket, avoiding accidents caused by misoperation. In addition, the high protection level of the socket can effectively prevent dust, moisture, and other substances from entering, further ensuring the reliability of electrical connections.

Furthermore, Festo's cable socket with cable KMEB - 1 - 24 - 2.5 - LED has good compatibility. It can seamlessly integrate with other automation products from Festo and devices from many brands on the market, providing users with more choices and convenience. In the integration process of industrial automation systems, this compatibility can greatly reduce the design and debugging difficulties of the system, improving the stability and performance of the entire system.

Application Scenarios of FESTO (Festo) Cable Socket with Cable KMEB - 1 - 24 - 2.5 - LED

In the field of industrial manufacturing, KMEB - 1 - 24 - 2.5 - LE

Cable Outlet with Connector KMEB-1-24-2.5-LED belongs to the Connection Technology series under FESTO company, model number KMEB-1-24-2.5-LED. To purchase or inquire about Cable Outlet with Connector KMEB-1-24-2.5-LED, you can directly contact 158 0047 0089 (Mr. He).