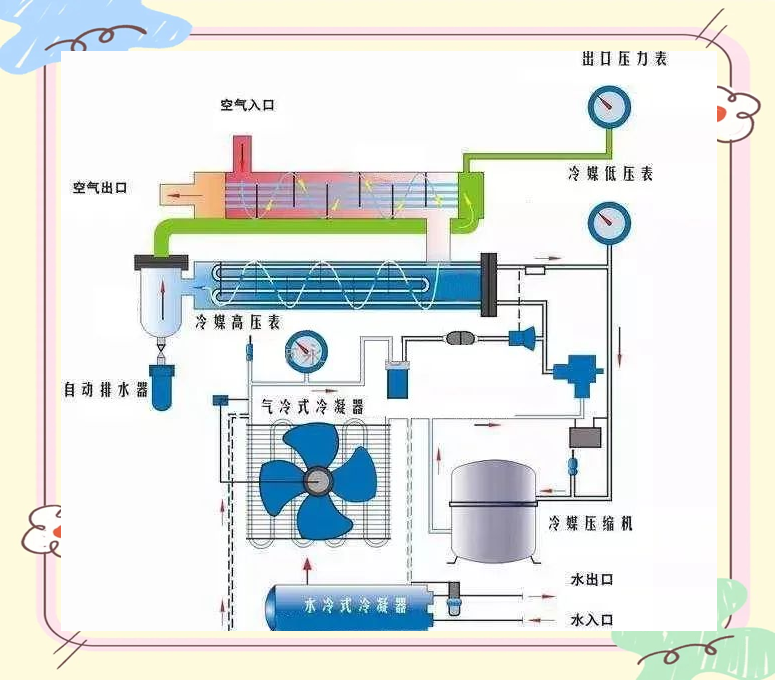

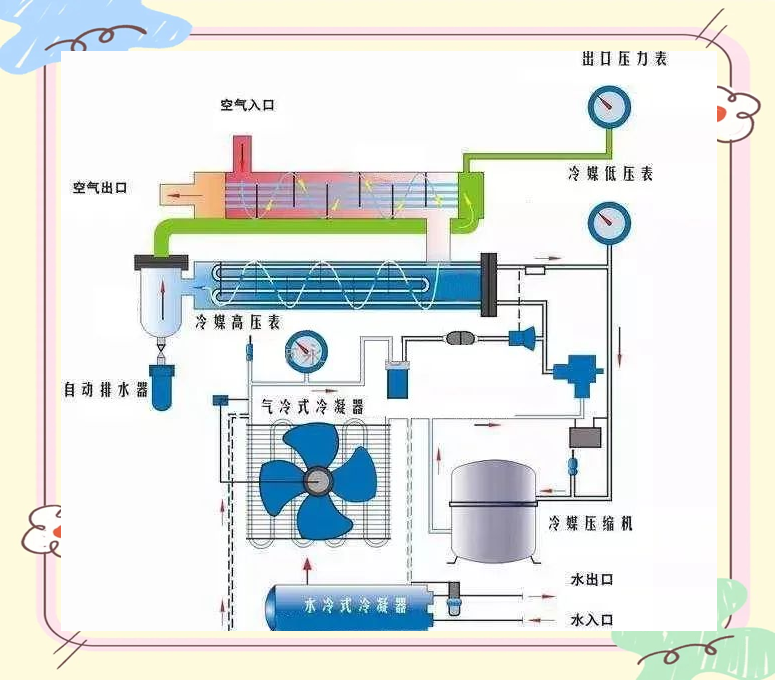

A compressed air system, in a narrow sense, mainly includes air source equipment, air source purification equipment, and associated connecting pipelines. However, in a broad sense, the system also covers pneumatic auxiliary components, pneumatic actuators, pneumatic control components, vacuum components, and many other components. Typically, the equipment equipped by an air compressor station can constitute a narrow sense compressed air system. Here is a typical compressed air system flow chart for your reference:

Air source equipment, that is, air compressors, are responsible for sucking in natural air from the atmosphere and converting it into compressed air with higher pressure through compression. Then, this compressed air will pass through purification equipment to remove impurities such as water, oil, and other contaminants from it. The air in nature is composed of a mixture of various gases, including water vapor. Air that contains a certain amount amount of water vapor is called humid air, while air that does not contain water vapor is called dry air. Since the air around us is all humid air, the working medium of the air compressor is naturally also humid air.Although the water vapor content in humid air is relatively low, it has a significant impact on the physical properties of humid air. In the purification process of compressed air, it is crucial to keep compressed air dry.

Under certain temperature and pressure conditions, the content of water vapor in humid air is limited. When the content of water vapor in humid air reaches its maximum possible value, this humid air is called saturated air. While humid air whose water vapor content has not reached its maximum possible value is called unsaturated air. When unsaturated air cools to a saturated state, there will be a phenomenon of liquid water droplets condensing, which is called "condensation".The phenomenon of condensation is very common in nature, for example, when the humidity is high in summer, the surface of tap water pipes is prone to forming water droplets; in the morning of winter, water droplets will appear on the glass windows of households, which are all the results of humid air cooling and condensation under constant pressure

The "dew point" mentioned in the above phenomenon refers to the temperature at which unsaturated air reduces its temperature while keeping the partial pressure of water vapor constant, and reaches saturation. When the temperature drops to the dew point, condensation will occur. It is worth noting that the dew point of humid air is not only related to temperature, but also closely related to the content of moisture in humid air. The higher the moisture content, the higher the dew point; conversely, the dew point will be lower.

In compressor engineering, the dew point temperature is of great significance. For example, when the outlet temperature of the air compressor is too low, the oil-gas mixture in the oil-gas tank may condense due to the low temperature, resulting in the lubricating oil containing water, which in turn affects the lubrication effect. Therefore, when designing the outlet temperature of the air compressor, it must be ensured that it is not lower than the dew point temperature under the corresponding partial pressure. Similarly, the atmospheric dew point refers to the dew point temperature of wet air at atmospheric pressure, while the pressure dew point refers to the dew point temperature of pressurized air.

The relationship between the two is related to the compression ratio: in the case of the same pressure dew point, the larger the compression ratio, the lower the corresponding atmospheric dew point will be.

The compressed air coming out of the air compressor is not pure, and it contains various pollutants. The main components include water, including liquid water droplets, water mist, and gaseous water vapor; residual lubricating oil mist, that is, mist-like oil droplets and oil vapor; solid impurities, such as rust mud, metal powder, rubber fine powder, etc.; as well as harmful chemical impurities and other impurities. These pollutants can cause serious impact on the pneumatic system.

The deterioration of lubricating oil can damage rubber, plastic, and sealing materials, causing valves to malfunction and contaminating products. Moisture and dust can cause metal devices and pipes to rust and corrode, and moving parts to seize or wear out, which in turn affects the normal operation and sealing of pneumatic components. In addition, moisture and dust can clog throttle holes or filters, and in cold areas, even cause pipes to freeze or crack due to the freezing of moisture.

Given the significant impact of air quality on the reliability and lifespan of pneumatic systems, it is particularly important to choose and use air source treatment systems correctly. So, what are the main sources of moisture in compressed air? It is mainly the water vapor that is sucked in along with the air by the air compressor. During the compression process, these water vapors will be squeezed into liquid water, thereby reducing the relative humidity of compressed air at the outlet of the air compressor.

At the same time, we also need to pay attention to the problem of oil pollution in compressed air. This mainly comes from the lubricating oil of air compressors, oil vapor and suspended oil droplets in the ambient air, as well as the lubricating oil used in pneumatic components in the system. Although most of the air compressors currently in use will inevitably bring in some dirty oil, by reasonably selecting and using air source treatment systems, we can effectively reduce the impact of these pollutants on the pneumatic system and ensure its stable and efficient operation.

In summary, for those pneumatic systems that do not need to add lubricants during operation, all kinds of oils and lubricants contained in compressed air are considered as oil pollutants. While for those working systems that need to add lubricants, the anti-rust paint and compressor oil contained in compressed air are identified as oil pollution impurities.

So, how do solid impurities enter compressed air? There are mainly two ways: Firstly, the surrounding atmosphere itself is mixed with impurities of various sizes. Although the air compressor intake is equipped with a filter, "aerosol" impurities below 5μm can still enter the air compressor with the intake air, and after mixing with oil and water in the compression process, they will enter the exhaust pipeline.

Secondly, during the operation of the air compressor, friction, impact between various parts, and the aging and falling off of seals will all generate solid particles such as metal particles, rubber dust, and carbon fission products. These particles are then carried into the air ducts.

In addition, we also need to understand the gas source equipment. Gas source equipment refers to the generator of compressed air - the air compressor. There are many types of air compressors, such as piston, centrifugal, screw, sliding vane, and scroll types, etc. The compressed air output from the air compressor contains a large amount of water, oil, and dust and other pollutants. Therefore, it is necessary to remove these pollutants through purification equipment to ensure the normal operation of the pneumatic system.

Air source purification equipment, also commonly known as after-treatment equipment, is a collective term for a series of equipment and devices. Together, they ensure the purity of compressed air. These devices include air storage tanks, dryers, and filters, etc.

The core function of the gas storage tank is to eliminate pressure pulsation, further separate moisture and oil in compressed air through adiabatic expansion and natural cooling, and store a certain amount, amount of gas. This function not only helps to alleviate the pressure when the gas consumption exceeds the out*****ir volume of the air compressor in a short time, but also can provide a short-term gas supply when the air compressor fails or loses power, thus ensuring the safe operation of pneumatic equipment.

A dryer, especially a refrigerated dryer, is an important equipment for removing water from compressed air. It utilizes the correlation between the partial pressure of water vapor in compressed air and temperature, and achieves dehydration and drying through cooling. In industrial compressed air systems, this dryer is an indispensable post-processing equipment, which can effectively reduce the water content of compressed air, that is, reduce its "dew point temperature".

Basic principle

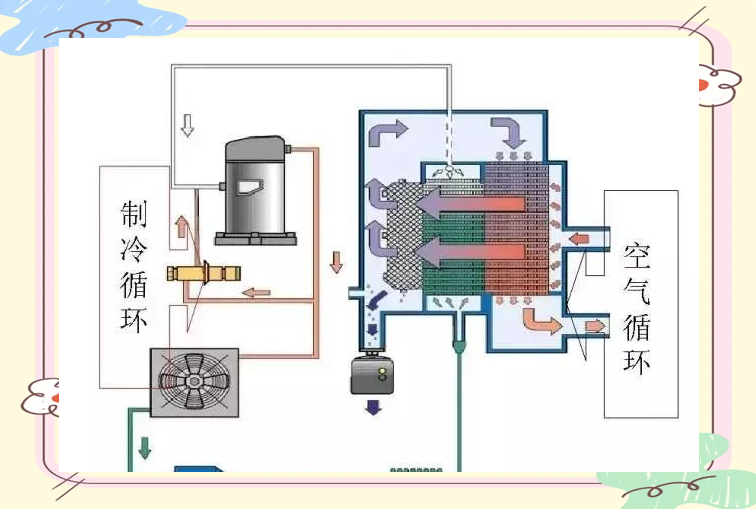

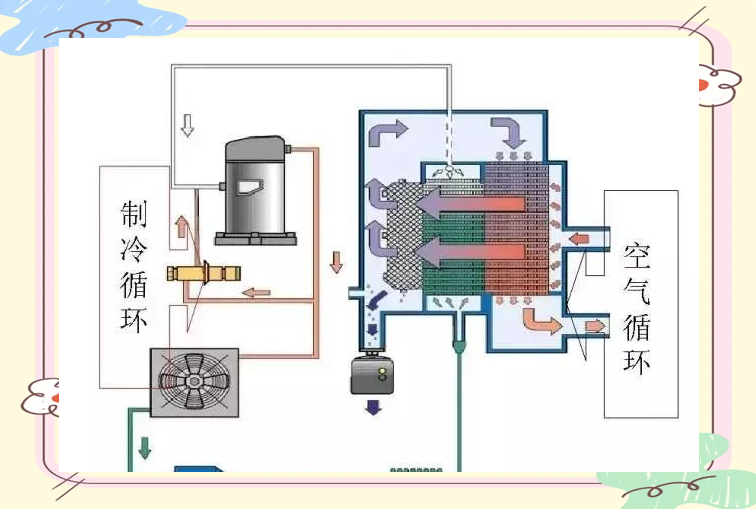

The removal of water from compressed air can be achieved through methods such as pressurization, cooling, and adsorption. Among these, the freeze-dryer utilizes the principle of cooling for water removal. In the process of compressed air compression by the air compressor, due to the increase in pressure, water vapor in the air will condense into water, thus achieving a preliminary water removal effect. However, the compressed air discharged from the air compressor still contains a large amount of water vapor and is in a saturated state. To further remove water, other methods need to be used, such as the cooling method adopted by the freeze-dryer.

The principle of cooling and dehumidification is to utilize the density limit of saturated water vapor. Within the range of pneumatic pressure (usually below 2MPa), the density of water vapor in saturated air mainly depends on temperature, not on air pressure. By reducing the temperature of the air, we can make the water vapor in saturated air condense into liquid water, thus achieving the purpose of dehumidification. The refrigeration dryer precisely utilizes this principle, cooling compressed air to below the dew point through the refrigeration system, making water vapor condense into water and discharge it, thereby ensuring the dryness of compressed air.

Gradually cool the compressed air to the lowest possible temperature, so that the density of water vapor contained in it decreases, thereby forming "condensation". After these condensation gather into small water droplets, they are discharged through a special drainage system, thus realizing the effective removal of moisture in compressed air. But it should be noted that the cooling process should be carried out above the freezing point to avoid the phenomenon of freezing blocking drainage.

In practical applications, the "pressure dew point temperature" of a refrigerated dryer is usually set within the range of 2~10℃. For example, when compressed air reaches a "pressure dew point" of 10℃ at a pressure of 7MPa, its "atmospheric dew point" is -16℃. This means that, under the condition that the ambient temperature is not lower than -16℃, compressed air will not produce liquid water when it is exhausted.

It is worth noting that the methods of removing water from compressed air are all relative, aiming to meet specific dryness requirements. Absolute removal of water is technically impossible, and excessive pursuit of unnecessary high dryness may lead to e****mic inefficiency.

Next, we will delve into the working principle of compressed air refrigeration dryers. By reducing the temperature of compressed air, water vapor will condense into droplets, which will then be discharged through the automatic drainage system. As long as we ensure that the ambient temperature downstream of the dryer outlet is higher than the dew point temperature of the evaporator outlet, we can effectively prevent the occurrence of secondary condensation.

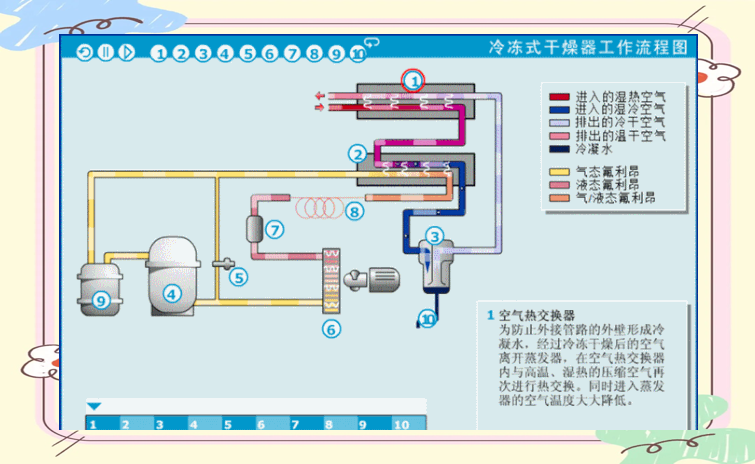

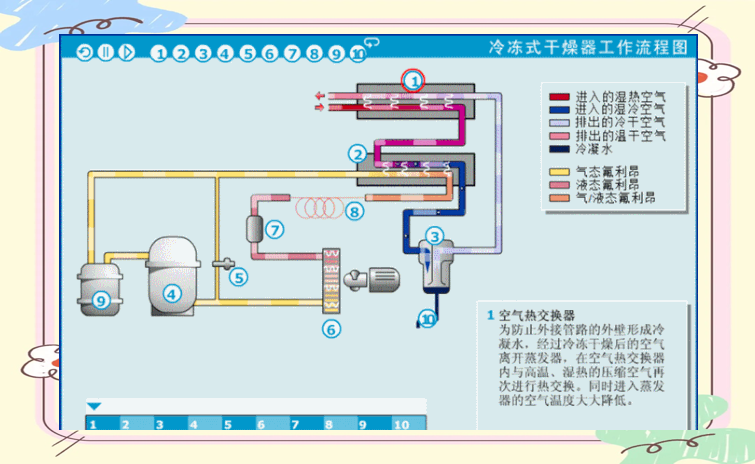

Detailed explanation of the workflow

In a refrigerated dryer, the process of removing water from compressed air follows a certain procedure. Firstly, compressed air is introduced into the dryer, and after being gradually cooled, the water vapor in it begins to condense into small water droplets. These water droplets are then efficiently discharged through a special drainage system, thus achieving effective removal of moisture in compressed air. Throughout the process, it is necessary to ensure that the cooling temperature is always above the freezing point to prevent ice formation from hindering the normal operation of the drainage system. Through such a workflow, the refrigerated dryer can effectively meet various dryness requirements and ensure the purity and stability of compressed air.

Detailed explanation of the compressed air process:

First of all, high-temperature compressed air enters the air heat exchanger (preheater) for preliminary cooling. Then, it enters the Freon/air heat exchanger (evaporator), where the compressed air is rapidly cooled to below the dew point temperature. The precipitated liquid water is separated from the compressed air in the water separator, and is discharged outside the machine through an automatic drainage device.

Moreover, if there is no low-temperature requirement for compressed air, the dried compressed air will return to the air heat exchanger and exchange heat with the high-temperature compressed air that just enters the refrigerant dryer. This not only allows us to effectively use the "waste cold" of the dried compressed air for pre-cooling and reduce the cooling load of the refrigerant dryer, but also prevents the low-temperature compressed air after drying from causing condensation, dripping, and rusting in the rear pipeline, which are secondary problems.

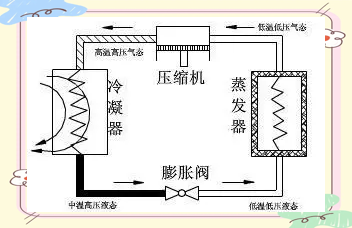

Here is the cooling process:

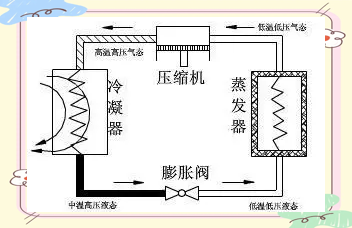

After the refrigerant Freon enters the compressor, it will be compressed, and both the pressure and temperature will increase. When its pressure is slightly greater than the pressure in the condenser, the high-pressure refrigerant vapor is discharged into the condenser. In the condenser, the refrigerant vapor exchanges heat with the low-temperature air or cooling water, thereby condensing into a liquid state.

Subsequently, the liquid refrigerant, after being reduced in pressure and temperature through the capillary tube/expansion valve, re-enters the Freon/air heat exchanger (evaporator). In the evaporator, the refrigerant absorbs the heat of the compressed air and vaporizes. In this way, the compressed air that has been cooled is continuously cooled, and the vaporized refrigerant is sucked back by the compressor, starting a new round of the cycle.

The refrigerant sequentially goes through four key processes in the system: compression, condensation, expansion (throttling), and evaporation, thereby completing a complete cycle. This cycle continues, effectively realizing the freezing of compressed air.

Next, let's take a closer look at the functions of each component:

Air heat exchanger: The main function of this component is to prevent the outer wall of the external pipeline from forming condensed water. After the air is freeze-dried, it undergoes another heat exchange with the high-temperature, humid compressed air here, thereby reducing the air temperature entering the evaporator.

Heat exchange: In the evaporator, the refrigerant absorbs heat and expands, transforming from a liquid state to a gaseous state, while the compressed air is cooled through heat exchange, causing the water vapor in the compressed air to condense from a gaseous state to a liquid state.

Water separator: This component is responsible for effectively separating the precipitated liquid water from compressed air. The higher the efficiency of the water separator, the lower the proportion of liquid water that re-evaporates into compressed air, which in turn makes the pressure dew point of compressed air lower.

Compressor: After the gaseous refrigerant enters the refrigeration compressor, it is compressed and becomes a gaseous refrigerant at high temperature and high pressure, preparing for the subsequent condensation process.

Bypass valve: This component is used to control the refrigeration temperature and ensure that the pressure dew point is stable between 1~6℃, to prevent the problem of ice blockage caused by the temperature of liquid water dropping below the freezing point.

Condenser: The condenser reduces the temperature of the refrigerant, making it change from a high-temperature gaseous state to a low-temperature liquid state, preparing for the subsequent evaporation process.

Filter: The filter is responsible for filtering out impurities in the refrigerant to ensure the purity of the refrigeration system.

Capillary tube/expansion valve: Through this component, the refrigerant expands in volume and decreases in temperature, eventually becoming a low-temperature, low-pressure liquid, preparing for entering the evaporator.

Gas-liquid separator: Ensures that only gaseous refrigerant can enter the refrigeration compressor, preventing the liquid impact phenomenon and compressor damage that may be caused by liquid refrigerant.

Automatic drain: Regularly discharge the liquid water accumulated at the bottom of the separator to keep the system dry and clean.

In addition, refrigeration dryers have the advantages of compact structure, convenient use and maintenance, as well as low maintenance costs, which are particularly suitable for occasions where the pressure dew point temperature of compressed air is not too low (above 0℃). While adsorption dryers use desiccants to dehumidify and dry compressed air that is forced to flow through them, and regenerative adsorption dryers are the most commonly used types in daily applications. At the same time, various filters are also equipped in the system to remove oil, dust, water, and other impurities in the air, so as to obtain clean compressed air.