The correct selection of the CMK2-LB-20-40 solenoid valve should be based on; electro or pneumatic control valve, with internal or external pilot air source, pneumatic or mechanical reset, specific types that comply with ATEX directives, suitable for potentially explosive working environments, MN1H single solenoid for N1 type solenoid coil, MFH single solenoid for F type solenoid coil, MDH single solenoid with D type solenoid coil, MEBH single solenoid with EB type solenoid coil, JMN1H double solenoid for N1 type solenoid coil, JMN1DH double solenoid for N1 type solenoid coil with main control signal, JMFH double solenoid for F type solenoid coil, JMFDH double solenoid for F type solenoid coil with main control signal, JMDH double solenoid with D type solenoid coil, JMEBH double solenoid with EB type solenoid coil, JMEBDH double solenoid with EB type solenoid coil and main control signal, 1 end plate assembly NEV for sealing the air path plate base, 2 quick connect fitting QS for connecting compressed air pipes with standard outer diameter, 3 base transition plate NAW for leading air ports 2 and 4 to the front side, 4 air path plate base NAV with bottom isolation piece NSC for sealing the common interface 1, 3, 5 on the air path plate base or isolating two air path plate bases to form different pressure zones, 6 intermediate plate NZV for connecting air path plate bases of different specifications 2 / 1.2-76, 7 base transition plate NAVW with air ports 2 and 4 at the bottom or front side 2 / 1.2-73, 8 muffler installed at the exhaust port. AEVULQ-50-25-P-A, AEVULQ-16-10-P-A-S26, DSM-63-270-CC-FW-A-B, DSM-63-270-CC-A-BEMME-AS-100-M-HS-AS, polyurethane air tube PUN-10X1,5-SG-4,8-BL-1/4D series pressure reducing valve LR-1/4-D-7-O-I-MIDI, M series pressure reducing valve LRB-M2-N1/2-16KAEVULQZ-50-10-P-A,, AEVULQ-32-10-A-P-A double acting anti-twist cylinder DZH-50-125-PPV-A, double acting anti-twist cylinder DZH-40-25-PPV-ALFR-D-DI-MAXI, LFR-1/4-D-7-MINI-AVN-20-L-T6-PQ4-VQ5-RO2, pressure reducing valve LR-M2-N1/2-04GK vacuum cup ESS-25X75-ON, vacuum cup VAS-40-1/4-NBRDFM-63-80-P-A-GF, DFM-25-50-P-A-GFCLR-50-20-R-P-A, LF/LFR/FRC-D-MAXI:ERSGRLA-1/8-B, VN-20-H-T6-

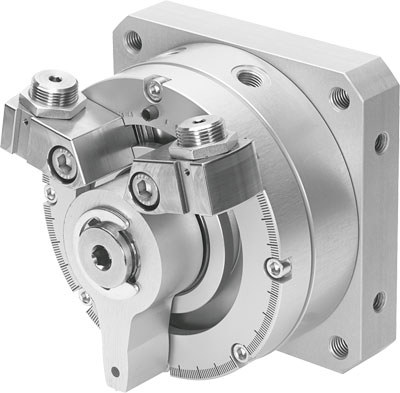

Double-acting cylinder CMK2-LB-20-40 belongs to the Air Pressure Cylinders series under CKD company, model number CMK2-LB-20-40. To purchase or inquire about Double-acting cylinder CMK2-LB-20-40, you can directly contact 158 0047 0089 (Mr. He).