FESTO(费斯托)接头QSH - 6简介

FESTO(费斯托), as a globally renowned supplier of pneumatic and electric technology, is known for the high quality, reliability, and innovation of its products. The QSH - 6 fitting is a representative product of Festo. This fitting is mainly used in pneumatic systems to connect different components and ensure the smooth transmission of gas.

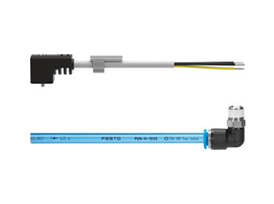

From an aesthetic perspective, the QSH - 6 fitting is designed with a compact size, which means it does not take up too much space during installation, making it particularly suitable for pneumatic equipment with limited space. It is made of high-quality materials, with a robust and durable housing capable of withstanding certain pressures and external impacts, ensuring long-term stable use in complex working environments.

In terms of connection performance, the QSH - 6 fitting has excellent sealing properties. It employs advanced sealing technology and materials, effectively preventing gas leakage and ensuring the efficient operation of the pneumatic system. At the same time, its connection method is simple and convenient, allowing operators to quickly install and remove the fitting, greatly improving work efficiency.

FESTO(费斯托)接头QSH - 6的技术参数与特点

Regarding technical parameters, the QSH - 6 fitting has an adapter diameter of 6mm, a common specification in pneumatic systems that allows for good matching with various pneumatic components. Its working pressure range is usually within a certain interval, generally meeting the normal working needs of most pneumatic equipment. The working temperature range is also quite extensive, allowing stable operation in different environmental temperatures, whether in high-temperature workshops or low-temperature cold storage environments.

The fitting has some unique features. First is its quick connect/disconnect function, a major highlight of the QSH - 6 fitting. Operators only need to simply insert or remove the fitting into or from the corresponding interface to complete the connection or disconnection operation, without the need for complex tools, greatly saving time on installation and maintenance. Second, it has good vibration resistance. In equipment with significant vibrations, ordinary fittings may loosen due to vibration, leading to gas leakage issues. The QSH - 6 fitting, through special structural design and material selection, can effectively resist the effects of vibration, maintaining connection stability.

Additionally, the QSH - 6 fitting has good corrosion resistance. In environments containing corrosive gases or liquids, fittings are prone to corrosion damage. When manufacturing the QSH - 6 fitting, Festo treated its surface with a special process, giving it strong corrosion resistance, extending the service life of the fitting, and reducing maintenance costs for equipment.

FESTO(费斯托)接头QSH - 6的应用场景与市场前景

The QSH - 6 fitting is widely applied in many fields. On automated production lines, the pneumatic system is a key part of realizing various motion controls, QSH - 6

Fitting QSH-6 belongs to the Connection Technology series under FESTO company, model number QSH-6. To purchase or inquire about Fitting QSH-6, you can directly contact 158 0047 0089 (Mr. He).