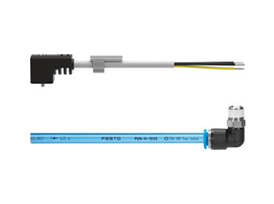

Basic Information of FESTO (Festo) Cable NEBC - D12G4 - ES - 5 - S - R3G4 - ET

FESTO (Festo), as a globally renowned supplier of automation technology, is known for the high quality and reliability of its products. The NEBC - D12G4 - ES - 5 - S - R3G4 - ET cable is an important product under the Festo brand with significant application value. Each part of the model has its specific meaning. “NEBC” represents the specific series to which the cable belongs, which usually means it has some common characteristics of the series cables, such as possibly unified standards in terms of protection level, electrical performance, etc. “D12G4” may indicate some key parameters of the cable, where “D12” may be related to the cable's outer diameter, interface size, or specifications of the equipment it applies to, and “G4” may represent the specifications or quantity of the internal conductors of the cable.

“ES” may be an identifier for some special function or design feature of the cable, possibly indicating that it has special properties such as anti-static, electromagnetic shielding, etc. “5” likely indicates that the length of the cable is 5 meters, which is a common cable length specification, convenient for connecting and laying in different application scenarios. “S” may represent the material of the cable's sheath or the protection level, such as possibly indicating a sheath with characteristics like waterproof, wear-resistant, etc. “R3G4” may involve some electrical parameters or connection methods of the cable again, and “ET” may be an identifier for the type of terminal or the applicable connection environment of the cable.

Application Scenarios of FESTO (Festo) Cable NEBC - D12G4 - ES - 5 - S - R3G4 - ET

In the field of industrial automation, the FESTO (Festo) cable NEBC - D12G4 - ES - 5 - S - R3G4 - ET has a wide range of applications. First, in automated production lines, it can be used to connect various sensors and actuators. For example, on an automated production line for car manufacturing, sensors need to accurately transmit information about the position and size of the parts detected to the control system, while actuators need to receive instructions from the control system to perform corresponding actions. This cable, with its stable electrical performance and reliable connection, ensures accurate and timely signal transmission between sensors and actuators, thereby ensuring the efficient operation of the production line.

In robotic applications, the cable also plays an important role. The joints and end effectors of robots need to be connected to the control system via cables to achieve precise motion control. The flexibility and durability of the NEBC - D12G4 - ES - 5 - S - R3G4 - ET cable can adapt to the frequent movement and bending of robots, while its good anti-interference performance ensures stable operation of robots in complex electromagnetic environments. In addition, in the food and beverage processing industry, due to

Cable NEBC-D12G4-ES-5-S-R3G4-ET belongs to the Connection Technology series under FESTO company, model number NEBC-D12G4-ES-5-S-R3G4-ET. To purchase or inquire about Cable NEBC-D12G4-ES-5-S-R3G4-ET, you can directly contact 158 0047 0089 (Mr. He).