Introduction to FESTO (Festo) Brand and the Hook-Up Coupling C - 3/8 - P - 9

FESTO (Festo) is a globally influential enterprise in the field of automation technology, renowned for providing high-quality, innovative pneumatic and electric products. Its products are widely used in various industries such as automotive, electronics, food and beverage, packaging, and more, offering strong support for the automation upgrade of global manufacturing industries.

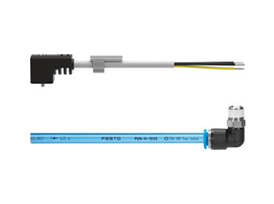

The hook-up coupling C - 3/8 - P - 9 is a representative product of FESTO. The letter 'C' stands for the type of coupling being a hook-up coupling; '3/8' indicates the interface size of the coupling is 3/8 inch, a common industrial specification that can fit numerous pipes and equipment of the same size; 'P' may represent specific material, performance, or design features of the coupling; '9' is likely the specific model number of the product, used to distinguish it from other products in the same series.

Features and Advantages of FESTO Hook-Up Coupling C - 3/8 - P - 9

Firstly, in terms of material, the FESTO hook-up coupling C - 3/8 - P - 9 is made of high-quality materials. This material has excellent corrosion resistance and can be used stably in different industrial environments, such as in damp conditions or where there is chemical erosion. It can maintain the performance of the coupling, reducing leakage and damage caused by corrosion, significantly extending the service life of the coupling.

Secondly, from a design perspective, the hook design of the coupling is very ingenious. The shape and size of the hook are carefully designed to fit closely with the corresponding pipes. During installation, simply insert the pipe into the hook part of the coupling, and the hook will tightly grip the inner wall of the pipe, forming a reliable sealed connection. This connection method is not only convenient and quick to install but also has excellent sealing performance, effectively preventing media leakage and ensuring the normal operation of the system.

Furthermore, the FESTO hook-up coupling C - 3/8 - P - 9 has good pressure resistance. It can withstand fluctuations in pressure within a certain range and still maintain a stable connection and seal in high-pressure environments. This makes it safe and reliable for use in industrial systems with high pressure requirements, providing a guarantee for the stable operation of the system.

In addition, the versatility of the coupling is also a significant advantage. The 3/8 inch interface size allows it to be compatible with numerous pipes and equipment of the same size on the market. Users do not have to worry about the coupling not matching other components during system upgrades or maintenance, reducing usage costs and replacement difficulties.

Application Scenarios and Installation Considerations for FESTO Hook-Up Coupling C - 3/8 - P - 9

The FESTO hook-up coupling C - 3/8 - P - 9 is widely used in various industries. In pneumatic systems, it can be used to connect air source pipes and pneumatic actuators, such as cylinders, solenoid valves, etc., ensuring stable air supply and precise operation of the pneumatic system.

Hooked Joint C-3/8-P-9 belongs to the Connection Technology series under FESTO company, model number C-3/8-P-9. To purchase or inquire about Hooked Joint C-3/8-P-9, you can directly contact 158 0047 0089 (Mr. He).