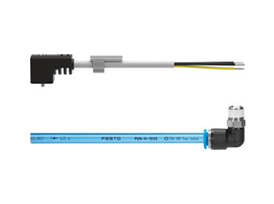

FESTO (Festo) Soft and Hard Tube Cutter ZRS Introduction

FESTO, as a globally renowned supplier of automation technology, is known for its products that are characterized by high quality, high performance, and innovative design. The Festo soft and hard tube cutter ZRS is one of its many excellent products, specifically designed for efficient and precise cutting of various soft and hard tubes.

This cutter is suitable for a variety of tube materials, including but not limited to pneumatic tubes, hydraulic tubes, plastic hoses, etc. It is widely used in many fields such as industrial automation, mechanical manufacturing, and automotive manufacturing. Whether on large-scale production lines or in small repair shops, ZRS can leverage its unique advantages to provide reliable cutting solutions for users.

The design of ZRS fully considers the user's needs and operational convenience. Its appearance is simple and elegant, with a compact structure that takes up little space, making it easy to install and place. At the same time, it also features good ergonomics; the design of the operating handle conforms to the natural gripping posture of the human hand, and long-term use will not cause fatigue, greatly improving work efficiency.

Features and Advantages of FESTO (Festo) Soft and Hard Tube Cutter ZRS

Precise cutting is a significant feature of ZRS. It employs advanced cutting technology and high-precision blades to ensure that the cut surface is flat and smooth, without burrs. This is crucial for applications that require high-quality tube cutting, such as in pneumatic systems, where a flat cut surface can ensure the sealing of tube connections, reducing the risk of gas leakage, thereby enhancing the stability and reliability of the system.

High cutting efficiency is also one of ZRS's important advantages. It has the capability for rapid cutting and can complete the task of cutting a large number of tubes in a short time. Compared with traditional cutting tools, ZRS can save a significant amount of time and labor costs. In addition, the cutter is equipped with an automatic feeding function, which further improves the continuity and efficiency of cutting.

Strong durability is a consistent feature of Festo products, and ZRS is no exception. Its housing is made of high-strength materials capable of withstanding certain impacts and vibrations, ensuring normal use even in harsh working environments. At the same time, its blades are specially treated to have good wear resistance and sharpness, with a long service life, reducing the frequency of blade replacement and lowering usage costs.

High safety is also a significant characteristic of ZRS. It is equipped with multiple safety protection devices, such as protective covers and safety switches, which can effectively prevent accidental injuries to operators during use. In addition, the operation of the cutter is simple and easy to understand, allowing even inexperienced operators to quickly get started, reducing the risk of operational errors.

Using and Maintaining FESTO (Festo) Soft and Hard Tube Cutter ZRS

Before using ZRS, it is necessary to conduct the necessary checks and adjustments. First, check if the power supply is normal, if the blades are securely installed, and if the protective devices are intact. Then, according to the type of tube material,

Soft and Hard Pipe Cutter ZRS belongs to the Connection Technology series under FESTO company, model number ZRS. To purchase or inquire about Soft and Hard Pipe Cutter ZRS, you can directly contact 158 0047 0089 (Mr. He).