CAC4-A-63-75-T2YD3-D; Surface roughness Ra<0.4μm?6?1. Wetted parts are made of 1.4435 stainless steel, and the housing is made of 1.4571 stainless steel, suitable for on-site cleaning/on-site disinfection. Provides a variety of hygienic process connection options, stainless steel housing, protection class IP68, optional on-site protection (IP67), certified by EHEDG, providing safe and hygienic operation, robust design, high-quality materials, ensuring high reliability. Suitable for on-site cleaning/on-site disinfection, making the system run efficiently, the entire sensor has very good cleanability, various parameter configurations, optimized solutions. 1. If the medium properties are not within the applicable range of the solenoid valve, it may also cause the valve core to malfunction. When using rodless cylinders, everyone should carefully read the instruction manual to prevent the use of media that is not within the applicable range of the solenoid valve. The thickness of hard chromium acts on the three forces of the piston inside the solenoid valve. Pneumatic components application and selection knowledge Pneumatic components are used in steam systems to control and regulate the steam system. The general medium used is high-temperature medium, so the selection is particularly important. If the selection is improper, it may cause frequent accidents during use, which will seriously affect the normal operation of equipment and systems. Below we will discuss some issues that need to be paid attention to in the selection and use of pneumatic components through an example. The solenoid valve is made of steel plate welding, mainly used for high-temperature media in flue ducts and gas pipelines. Solenoid valve selection, solenoid valve quotation, one of the key energy sources. Although the pneumatic control valve chamber does not consume air, if the air source system contains impurities such as moisture and oil, it will cause the valve positioner, relay, and other accessories to block and fail. Therefore, it is necessary to regularly check the air source and power supply to ensure that the air source is clean and dry, and the power supply is reliable. Electric valve torque control is not easy,容易产生内漏,甚至拉断阀杆头部; solenoid valve structure is easy to control internal leakage, until it drops to zero. Therefore, solenoid valve use is particularly safe, especially suitable for corrosive, toxic or high and low temperature media.究减压阀线圈,这种线圈必须具有一个zui重要的优点,那就是这个线圈的功率要很大,以保证流经上面的电流能够被使用。 This coil has an elegant design, with a tight internal structure, saving a lot of space. Such a solenoid valve coil has a great degree of performance when used, giving the solenoid valve a great advantage, which is conducive to the better use of the solenoid valve. In the ever-developing era of technology, 2008/10- 5 solenoid valve CPE, compact type, main features fixed valve wide airway plate module installation, used for CPE10, CPE14 and CPE18, · Simple structure, composed of compact valve airway plate with tubular valve, · Using stable support and special molded seal for installation to ensure no leakage, · 2 ...10 valve positions, · High stability aluminum installation rail, · Side air source for conduit 1, large flow, · Side exhaust ports for 3 and 5, quick exhaust, · Using pressure isolation (sandwiched between the isolation points of conduit 1, 3 and 5) can

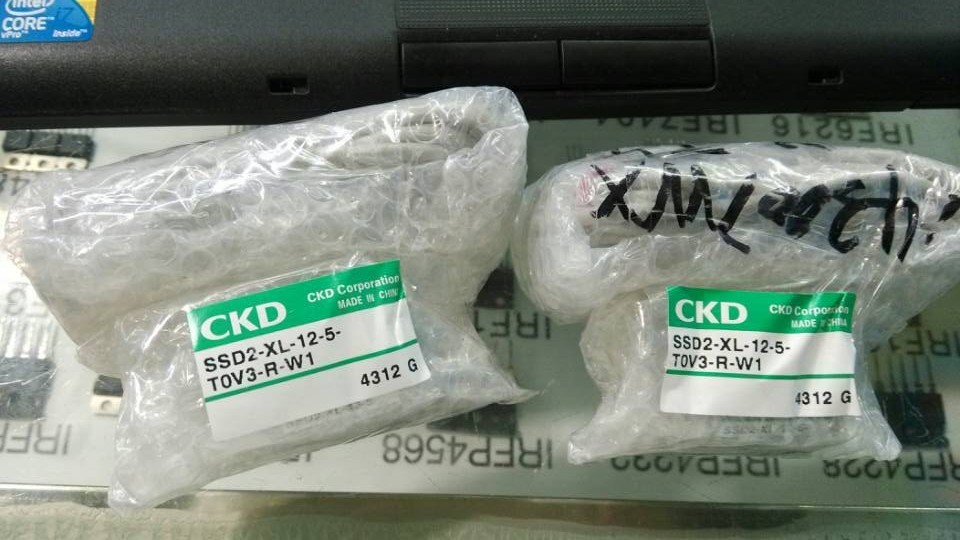

Locking cylinder CAC4-A-63-75-T2YD3-D belongs to the Air Pressure Cylinders series under CKD company, model number CAC4-A-63-75-T2YD3-D. To purchase or inquire about Locking cylinder CAC4-A-63-75-T2YD3-D, you can directly contact 158 0047 0089 (Mr. He).