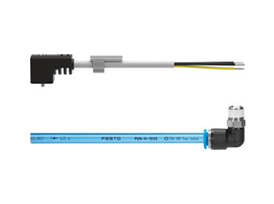

Introduction to FESTO (Festo) Plastic Air Hose PAN - 12X1,75 - SW

FESTO (Festo), as a globally renowned supplier of automation technology, is known for the high quality and reliability of its products. The PAN - 12X1,75 - SW plastic air hose is a representative product of the Festo brand. In the model number, 'PAN' stands for the series of air hoses it belongs to, '12' indicates that the outer diameter of the hose is 12mm, '1.75' refers to the wall thickness of the hose being 1.75mm, and 'SW' may be a specific version or functional identifier of the hose.

From a material perspective, it uses high-quality plastic material, which has good flexibility and corrosion resistance. The flexibility allows the hose to easily bend during installation, adapting to various complex pipeline layouts, reducing the difficulty and time cost of installation. The corrosion resistance ensures that the hose can work stably for a long time in different working environments, such as humid and chemical-containing places, extending the service life of the hose.

In terms of appearance, the Festo plastic air hose PAN - 12X1,75 - SW typically has a smooth and uniform surface, which not only helps to reduce the resistance of airflow inside the hose but also makes the hose more aesthetically pleasing. At the same time, its color is generally the standard industrial color, making it easy to identify and distinguish among many pipelines.

Performance Characteristics of FESTO (Festo) Plastic Air Hose PAN - 12X1,75 - SW

Firstly, in terms of pressure resistance, this hose performs excellently. It can withstand a certain range of pressure, ensuring stable transmission of compressed air in pneumatic systems. This is crucial for industrial equipment with high air pressure requirements, ensuring the normal operation of the equipment and avoiding faults caused by unstable air pressure.

Secondly, the sealing performance of this hose is extremely good. Festo uses advanced manufacturing processes in the production process, allowing the hose's interface to connect tightly and prevent gas leakage. Good sealing not only improves the efficiency of the pneumatic system, reducing energy waste, but also avoids safety hazards caused by gas leakage.

Furthermore, the PAN - 12X1,75 - SW plastic air hose has excellent temperature resistance. It can work normally within a certain temperature range, whether in high-temperature environments or low-temperature environments, maintaining the stability of its physical properties. This makes it suitable for various industrial scenarios, such as high-temperature foundries and low-temperature cold storage warehouses.

In addition, this hose also has a low friction coefficient. This means that the energy loss of airflow inside the hose is smaller, allowing for more efficient transmission of gas. At the same time, a low friction coefficient reduces the wear of the hose's inner wall, further extending the service life of the hose.

Application Scenarios and Advantages of FESTO (Festo) Plastic Air Hose PAN - 12X1,75 - SW

Plastic Air Hose PAN-12X1,75-SW belongs to the Connection Technology series under FESTO company, model number PAN-12X1,75-SW. To purchase or inquire about Plastic Air Hose PAN-12X1,75-SW, you can directly contact 158 0047 0089 (Mr. He).