FESTO (Festo) Plug B-1 Brand Background and Basic Introduction

FESTO (Festo), as a globally renowned supplier of automation technology, holds a high reputation in the industrial field. Its products are known for their high quality, reliability, and innovation, and are widely used in various industries such as automotive, electronics, food and beverage. The Festo plug B-1 is a representative product of the brand.

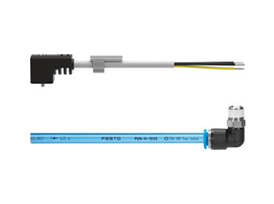

The Festo plug B-1 is mainly used for blocking various pipes and interfaces to prevent fluid leakage and ensure the sealing and stability of the system. It adopts advanced manufacturing processes and high-quality materials, featuring excellent performance and durability. In terms of appearance design, the plug B-1 is simple and elegant, with precise size specifications, capable of perfectly matching other Festo pneumatic components, providing users with a one-stop solution.

FESTO (Festo) Plug B-1 Features and Advantages

Firstly, in terms of materials, the Festo plug B-1选用 special engineering plastics or metal materials. These materials have good corrosion resistance and can be used in various harsh working environments, such as humid and acidic environments. For example, in the pipeline systems of the chemical industry, the plug B-1 can resist the erosion of chemicals for a long time, ensuring that its sealing performance is not affected.

Secondly, the sealing performance of the plug B-1 is very excellent. It adopts a unique sealing structure design, capable of achieving a tight sealing effect, effectively preventing the leakage of gas or liquid. Whether under high or low pressure working conditions, it can maintain a good sealing state. In some pneumatic control systems with high sealing requirements, the Festo plug B-1 can ensure the normal operation of the system, avoiding energy loss and equipment failure caused by leakage.

Furthermore, the plug has good installation convenience. Its design conforms to ergonomic principles, allowing users to easily install and remove. At the same time, its size is standardized, capable of matching with common pipes and interfaces on the market, without the need for complex modifications. This not only saves installation time and cost but also improves work efficiency.

In addition, the Festo plug B-1 also has outstanding mechanical properties. It can withstand certain external impacts and vibrations without being easily damaged. In some industrial equipment with large vibrations, the plug B-1 can still maintain a stable sealing state, ensuring the safe operation of the equipment.

FESTO (Festo) Plug B-1 Application Scenarios and Market Prospects

The application scenarios of the Festo plug B-1 are very extensive. In pneumatic systems, it can be used to block the interfaces of components such as cylinders and valves, preventing gas leakage and ensuring the stability of system pressure. In hydraulic systems, the plug B-1 also plays an important role, blocking the openings of pipes to prevent the leakage of hydraulic oil. In addition, in the production equipment of food and beverage, pharmaceutical and other industries, the plug B-1 is also widely used to ensure the hygiene of the production process.

Plug B-1 belongs to the Connection Technology series under FESTO company, model number B-1. To purchase or inquire about Plug B-1, you can directly contact 158 0047 0089 (Mr. He).