FESTO (Festo) Plug MSSD - EB Introduction

FESTO (Festo), as a globally renowned supplier of automation technology, is known for the high quality, reliability, and innovation of its products. The FESTO plug MSSD - EB is an electrical connection component of significant application value offered by the company.

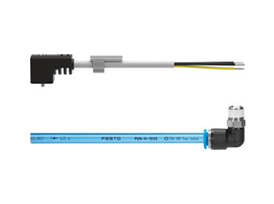

From the perspective of design, the MSSD - EB plug features a compact and refined structure. This design not only saves installation space but also facilitates layout in various complex industrial environments. The housing material is carefully selected for its excellent wear resistance, corrosion resistance, and impact resistance, allowing for long-term stable operation under harsh working conditions, effectively protecting the internal electrical connections and reducing the probability of faults caused by external factors.

Electrical performance-wise, the MSSD - EB plug possesses outstanding conductivity and insulation properties. It ensures stable current transmission, reduces signal interference, and thus guarantees the normal operation of connected equipment. At the same time, its insulation performance meets strict safety standards, effectively preventing electrical leakage and other safety incidents, providing reliable safety protection for operators and equipment.

Applications of FESTO (Festo) Plug MSSD - EB

Industrial automation production lines are one of the main application scenarios for the MSSD - EB plug. On these production lines, a vast amount of electrical signal transmission and power supply between various equipment is required. The MSSD - EB plug, with its stable performance and reliable connection, can meet the needs of high-speed and efficient operation of production lines. For example, in the control circuit of a robotic arm, the MSSD - EB plug can ensure precise signal transmission, allowing the robot to accurately perform various actions, thereby improving production efficiency and product quality.

In the food and beverage industry, hygiene and safety are of utmost importance. The design of the MSSD - EB plug complies with food industry hygiene standards; its housing material is easy to clean and disinfect, effectively preventing the growth of bacteria. Moreover, its high protection rating prevents the ingress of liquids and dust, ensuring normal operation in damp and dusty environments. Therefore, it is widely used in food processing equipment, filling production lines, and other equipment.

Additionally, the MSSD - EB plug plays a significant role in the automotive manufacturing and electronic equipment manufacturing industries. On automotive production lines, it is used to connect various sensors, actuators, and control units, enabling automated production and inspection of vehicles. During the electronic equipment manufacturing process, the MSSD - EB plug ensures stable connections between electronic components, enhancing the reliability and stability of the products.

Advantages and Future Development of FESTO (Festo) Plug MSSD - EB

The FESTO plug MSSD - EB has many advantages. First, its installation is very convenient and fast. Its unique plug-and-play design allows operators to easily connect and disconnect, significantly reducing installation time.

Plug MSSD-EB belongs to the Connection Technology series under FESTO company, model number MSSD-EB. To purchase or inquire about Plug MSSD-EB, you can directly contact 158 0047 0089 (Mr. He).