The festo rodless cylinder DGC-K-50-600-PPV-A-GK has no piston rod, only a slider in the middle. This slider has an internal valve core that directly drives it, or it can be driven by a high-strength permanent magnet outside the piston through a high-strength permanent magnet inside the slider, to achieve the purpose of common movement. The universal valve island has a higher requirement for air quality; if there are many air impurities, it may need maintenance or replacement of seals after a period of time. The universal valve island does not have a piston rod protruding outside, saving a lot of space and making the entire machine more aesthetic. Compared with a regular air filter, the universal valve island can reduce space by 50%, and there is no need to install hexagonal rods to prevent rotation and other accessories. The rodless air filter saves space, is easy to install, and simple to maintain. The flow capacity of the counter will increase. During the water linkage test, it is impossible to quickly reach the normal state of the simulated process conditions, and the counter is used for a long time at a small opening degree. Due to the action of unbalanced forces, serious instability will occur. Therefore, the regulating valve will produce strong vibrations and emit piercing noises, causing the valve core to break quickly. However, under normal process conditions, the opening degree of the counter is moderate, and even a small opening degree is temporary, so the regulating valve can be used normally and safely. The structural principle of the pressure reducing valve is particularly suitable for making large-diameter valves. The groove butterfly valve is widely used in general industries such as petroleum, gas, chemical, water treatment, and is also applied to the cooling water system of thermal power stations. Common butterfly valves include wafer type butterfly valves and flange type butterfly valves. The wafer type butterfly valve is connected between two pipe flanges with double-headed bolts, and the flange type butterfly valve has flanges on the valve, which are connected to the pipe flanges with bolts at both ends of the valve. The strength performance of the valve refers to the ability of the valve to withstand the pressure of the medium. The valve is a mechanical product that withstands internal pressure, so it must have sufficient strength and rigidity to ensure long-term use without rupture or deformation. The pressure reducing valve is an element that relies on the pressure difference of its own medium to automatically control the flow rate, with the ability to stabilize the flow rate, and can be used to completely solve the problem of hydraulic imbalance. The self-operated flow control valve is simple to install and easy to adjust; in use, the energy-saving effect is obvious, saving 25-30% electricity, 15-20% coal, and increasing the heating area by 25-30%. It is beneficial for stable operation and improving heating quality. In the renovation of the mixing water system, after hydraulic calculation, corresponding flow control valves are installed according to factors such as heating area, circulating flow, and heating pipe diameter. According to the temperature, the flow is adjusted, and the unique function of the self-operated flow control valve is used to stabilize the pressure, flow, and temperature of the mixed water, ensuring the flow balance and adjustment between each mixing station, achieving balanced operation. Among them, the linear control of electromagnetic force will change the braking pressure of the wheel filter, but this linear control will bring some negative effects. Taking the maintenance of the braking pressure of the wheel filter as an example, when the braking pressure of the wheel filter enters the maintenance state, the NO control valve starts to work. Due to the linear control of the NO control valve, the conduction time of the control coil is increased, which in turn causes the temperature of the control coil to rise, and then increases the resistance value of the control coil. The increase in resistance value leads to a decrease in control current, forcing an increase in the opening area of the control valve,

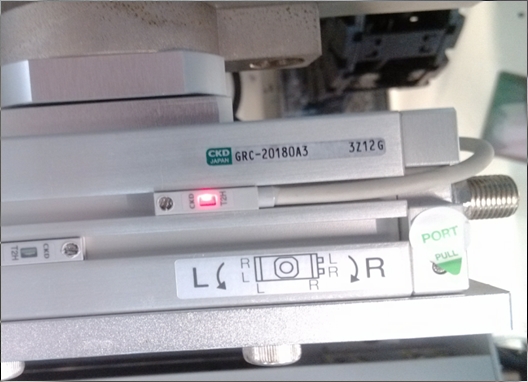

Rodless Cylinder DGC-K-50-600-PPV-A-GK belongs to the Air Pressure Cylinders series under CKD company, model number DGC-K-50-600-PPV-A-GK. To purchase or inquire about Rodless Cylinder DGC-K-50-600-PPV-A-GK, you can directly contact 158 0047 0089 (Mr. He).