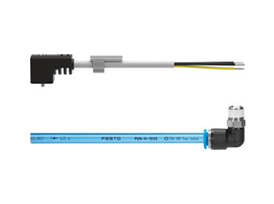

FESTO (Festo) T-type Quick-Connect Coupler QST - 10 - 50 Introduction

FESTO, as a globally renowned supplier of pneumatic and automation technology, is known for the high quality, performance, and reliability of its products. The T-type quick-connect coupler QST - 10 - 50 is one of many outstanding products from FESTO. This coupler is widely used in the field of industrial automation and provides a convenient and efficient solution for connecting pneumatic systems.

“QST” represents the series name of the coupler, which is a specific model series of FESTO quick-connect couplers. “10” indicates the size of the coupler's connection tube diameter is 10mm, a common specification in many industrial pneumatic systems that can meet most equipment's requirements for gas flow and pressure. “50” usually represents some specific parameter or specification of the coupler, possibly related to the length of the coupler, the range of operating pressure, etc.

The FESTO T-type quick-connect coupler QST - 10 - 50 employs advanced design concepts and manufacturing processes, ensuring the sealing and durability of the coupler. Its unique T-shape design allows a single pipeline to branch out in two directions, greatly enhancing the flexibility of the pneumatic system layout and facilitating users to build and modify the system according to actual needs.

Features and Advantages of FESTO (Festo) T-type Quick-Connect Coupler QST - 10 - 50

Firstly, in terms of installation, QST - 10 - 50 has significant advantages. It features a quick-connect design that does not require any tools; simply insert the air tube into the coupler to complete the connection, greatly saving installation time and labor costs. Moreover, this quick-connect method reduces the risk of leakage caused by improper installation, enhancing the reliability of the system. Even in complex industrial environments, personnel can quickly and easily complete the installation and removal of the coupler, facilitating system maintenance and repair.

Secondly, the coupler's sealing performance is excellent. During the design and manufacturing process, FESTO uses high-quality sealing materials and precise manufacturing techniques to ensure that the coupler maintains good sealing effects even under high pressure and high-speed airflow conditions. This not only prevents gas leakage and reduces energy waste but also ensures the stable operation of the pneumatic system and improves the efficiency of equipment operation. Additionally, good sealing performance effectively prevents external dust, moisture, and other impurities from entering the system, extending the service life of other components within the system.

Furthermore, QST - 10 - 50 has high durability. Its housing is made of high-strength engineering plastic or metal materials, possessing good impact resistance, wear resistance, and corrosion resistance. Under harsh industrial conditions, such as high temperatures, humidity, and dusty environments, the coupler can still function normally and is not easily damaged. This allows FESTO's coupler to adapt to various complex industrial application scenarios, providing users with long-term stable service.

FESTO (Festo) T-type Quick-Connect Coupler

T-shaped Quick Connector QST-10-50 belongs to the Connection Technology series under FESTO company, model number QST-10-50. To purchase or inquire about T-shaped Quick Connector QST-10-50, you can directly contact 158 0047 0089 (Mr. He).