FESTO (Festo) Electrical Junction Board VAVE-L1-1VH2-LP Overview

FESTO (Festo), as a renowned company in the field of automation technology, has launched the electrical junction board VAVE-L1-1VH2-LP, which plays an important role in industrial automation systems. This electrical junction board is a meticulously designed product by Festo, aiming to provide users with efficient, stable, and reliable electrical connection solutions.

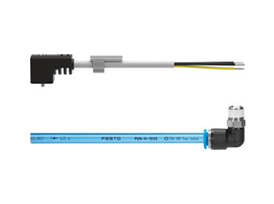

From the perspective of design, VAVE-L1-1VH2-LP adopts a compact and reasonable structural layout. Its dimensions are precisely planned to adapt to different installation space requirements, whether in small automation equipment or in large industrial production lines, it can be conveniently installed and integrated. This compact design not only saves valuable installation space but also makes the wiring of the entire system more neat and orderly, reducing the potential faults caused by messy wiring.

In terms of materials, Festo has chosen high-quality materials to manufacture this electrical junction board. These materials have good electrical insulation properties, corrosion resistance, and mechanical strength. The electrical insulation properties ensure that there will be no mutual interference and short circuits between circuits in complex electrical environments, ensuring the normal operation of the system. Corrosion resistance allows the junction board to be used for a long time in harsh industrial environments such as dampness and chemical corrosion, extending its service life. Sufficient mechanical strength ensures that the junction board will not be damaged during installation and use due to external force impact.

FESTO (Festo) Electrical Junction Board VAVE-L1-1VH2-LP Functional Features

VAVE-L1-1VH2-LP has rich and practical functional features, making it stand out among many similar products. First of all, it has excellent electrical connection performance. The junction board can provide stable electrical transmission, ensuring the accurate transmission of signals and power. Whether it is a weak control signal or a high-power power supply, it can be reliably connected through it. This is crucial for the collaborative work of various equipment in industrial automation systems, ensuring that the equipment operates accurately according to the predetermined program, improving production efficiency and product quality.

Secondly, VAVE-L1-1VH2-LP has good compatibility. It can seamlessly connect with various pneumatic and electric components of Festo, such as solenoid valves, cylinders, etc. This compatibility allows users to be more flexible in choosing and matching different components when building automation systems, meeting diversified production needs. At the same time, it can also connect with some electrical equipment of other brands, further expanding its application range.

In addition, this electrical junction board also has certain protective functions. It adopts a sealed design, which can effectively prevent dust, moisture, and other impurities from entering the internal circuit, protecting the electrical components from damage. In some industrial occasions with high environmental requirements, such as food processing, electronic manufacturing, etc., this protective function is particularly important, ensuring that the system operates in a clean

Electrical connection board VAVE-L1-1VH2-LP belongs to the Connection Technology series under FESTO company, model number VAVE-L1-1VH2-LP. To purchase or inquire about Electrical connection board VAVE-L1-1VH2-LP, you can directly contact 158 0047 0089 (Mr. He).