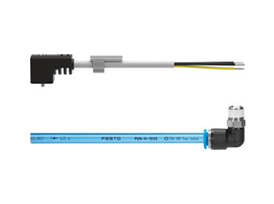

FESTO(费斯托)插座MSSD - EB Overview

FESTO, as a globally renowned supplier of automation technology, is known for its products' high quality, innovation, and reliability. The FESTO(费斯托)socket MSSD - EB is an outstanding product in the field of electrical connections. This socket is specifically designed for industrial automation scenarios, aiming to provide stable, efficient, and safe connection solutions for various electrical equipment.

The MSSD - EB socket adopts advanced design concepts and manufacturing processes, featuring excellent performance. It is capable of adapting to complex and ever-changing industrial environments, ensuring stability and reliability of electrical connections under conditions of high temperature, humidity, or dust. The compact design of the socket saves space and facilitates installation and layout in various devices and systems. Meanwhile, its housing is made of high-strength materials, providing good protection and effectively preventing external factors from damaging the internal structure of the socket.

Features and Advantages of FESTO(费斯托)Socket MSSD - EB

Firstly, in terms of electrical performance, the MSSD - EB socket has characteristics of low resistance and high conductivity. This means that during the current transmission process, energy loss can be reduced, and energy efficiency can be improved. At the same time, low resistance can also reduce the heating phenomenon of the socket during operation, extending the service life of the socket. In addition, the socket can withstand large current loads, meeting the high-power electrical needs of industrial equipment.

Secondly, in terms of safety, the MSSD - EB socket performs excellently. It adopts multiple safety protection designs, such as having anti-electric shock protection, effectively preventing electric shock accidents during the plugging and unplugging of plugs by operators. The internal structure of the socket also has good insulation performance, preventing leakage. Moreover, the socket has passed strict safety certifications, conforming to international standards, providing users with reliable safety assurance.

Furthermore, the MSSD - EB socket has good compatibility. It can match various types of plugs, making it convenient for users to use in different devices and systems. Whether it is a standard industrial plug or a plug with special specifications, it can achieve good connection with the socket. In addition, the socket supports various installation methods, allowing users to choose suitable installation methods based on actual needs, increasing the flexibility of use.

Additionally, in terms of durability, the FESTO(费斯托)socket MSSD - EB performs outstandingly. Its housing is made of impact-resistant and wear-resistant materials, capable of withstanding a certain degree of external force impact and friction. At the same time, the internal contacts of the socket are made of high-quality metal materials, possessing good oxidation resistance and corrosion resistance, maintaining stable electrical performance during long-term use.

Application Scenarios of FESTO(费斯托)Socket MSSD - EB

In industrial automation production lines, the MSSD - EB socket plays an important role. Since

Socket MSSD-EB belongs to the Connection Technology series under FESTO company, model number MSSD-EB. To purchase or inquire about Socket MSSD-EB, you can directly contact 158 0047 0089 (Mr. He).