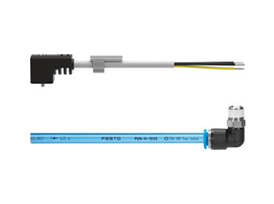

FESTO (Festo) Connector QSY - 6 - 4 Introduction

FESTO, as a globally renowned supplier of automation technology, is known for its products' high quality, performance, and reliability. The FESTO connector QSY - 6 - 4 is one of many high-quality products in its range. This connector is widely used in the field of industrial automation and plays a key role in connecting different components within pneumatic systems.

In terms of the model, 'QSY' represents the series of the connector, while '6 - 4' has a specific meaning. The '6' typically indicates that the diameter of the connecting pipe at one end of the connector is 6mm, and the '4' indicates that the diameter at the other end is 4mm. This design with different pipe diameters allows it to adapt to the connection needs of various pipe specifications, providing more flexibility for the construction of pneumatic systems.

The connector utilizes advanced manufacturing processes and high-quality materials, ensuring stable operation in various complex industrial environments. Its compact design and reasonable structure not only save space but also allow for quick and easy installation, effectively improving the installation efficiency of pneumatic systems.

Features of the FESTO (Festo) Connector QSY - 6 - 4

Firstly, in terms of sealing performance, the FESTO connector QSY - 6 - 4 performs exceptionally well. It employs a special sealing structure and sealing materials, effectively preventing gas leakage. In pneumatic systems, gas leakage can not only lead to energy waste but also affect the normal operation of the system. The excellent sealing performance of this connector ensures the efficient and stable operation of pneumatic systems, reducing faults and maintenance costs caused by leakage.

Secondly, the connector has good corrosion resistance. Industrial environments often contain various corrosive substances, such as chemical gases and moisture. The materials of the FESTO connector QSY - 6 - 4 are specially treated to resist the erosion of these corrosive substances, extending the service life of the connector. This makes it reliable even in harsh industrial environments, such as the chemical and food processing industries.

Furthermore, the FESTO connector QSY - 6 - 4 has high connection strength. It can withstand certain pressures and tensile forces, ensuring that the connector will not loosen or fall off due to external forces during the operation of the pneumatic system. This high connection strength guarantees the safety and stability of the pneumatic system, preventing accidents caused by loose connectors.

In addition, the operation of the connector is very convenient. It features a user-friendly design, allowing operators to easily install and remove it. When maintaining or modifying pneumatic systems, connectors can be quickly replaced, reducing downtime and improving production efficiency.

Applications of the FESTO (Festo) Connector QSY - 6 - 4

In automated production lines, the FESTO connector QSY - 6 - 4 has a wide range of applications. Automated production lines typically require a large number of

Fitting QSY-6-4 belongs to the Connection Technology series under FESTO company, model number QSY-6-4. To purchase or inquire about Fitting QSY-6-4, you can directly contact 158 0047 0089 (Mr. He).