FESTO (Festo) Base Kit MS12 - AGI Overview

FESTO (Festo), as a globally renowned supplier of automation technology, is known for its products' high quality, innovative design, and superior performance. The base kit MS12 - AGI is one of many excellent products from Festo. This base kit has been carefully developed by Festo to meet the actual needs of the industrial automation field, aiming to provide stable and reliable support and connection solutions for various automation equipment.

The MS12 - AGI base kit boasts high versatility and compatibility. It can perfectly match a variety of Festo's pneumatic and electric components, such as cylinders, valve islands, sensors, etc. This allows users to more flexibly combine and configure various components when building automation systems, enhancing the overall performance and efficiency of the system. At the same time, the design of the kit fully considers the complex environment of industrial sites, possessing good protection performance, and can adapt to different conditions such as temperature, humidity, and dust, ensuring that the equipment can operate stably even in harsh environments.

Features of the FESTO (Festo) Base Kit MS12 - AGI

Firstly, in terms of structural design, the MS12 - AGI adopts a modular design concept. This design makes the installation and disassembly of the kit very convenient, allowing users to quickly assemble and adjust the kit according to actual needs. The modular structure also facilitates later maintenance and upgrades; when the system needs to add or replace certain functions, simply operate the corresponding modules, greatly reducing maintenance costs and downtime.

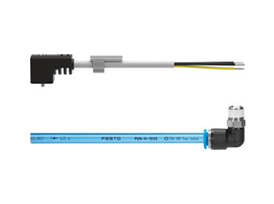

Secondly, the base kit has excellent connection performance. It is equipped with advanced electrical and pneumatic connection interfaces, capable of achieving fast and reliable signal transmission and gas supply. The electrical interface adopts a standardized design, ensuring compatibility with various control equipment, making system integration convenient for users. The pneumatic interface has been carefully designed to effectively reduce gas leakage, improving the efficiency and stability of the pneumatic system.

Furthermore, the MS12 - AGI is very particular about the choice of materials. Its main structure uses high-strength aluminum alloy material, which not only has good mechanical properties and can withstand large loads but is also light in weight, making it easy to transport and install. At the same time, aluminum alloy material also has good corrosion resistance, which can extend the service life of the kit and reduce the cost of equipment replacement.

In addition, the kit also has good heat dissipation performance. During the operation of industrial automation equipment, a large amount of heat is generated, which, if not dissipated in time, will affect the performance and life of the equipment. The MS12 - AGI achieves optimized heat dissipation design, capable of quickly and effectively dissipating heat, ensuring that the equipment operates within a normal temperature range.

Application Scenarios of the FESTO (Festo) Base Kit MS12 - AGI

In the automotive manufacturing industry, the MS12 - AGI base kit has a wide range of applications. On the automotive production line, a large number of

Base Kit MS12-AGI belongs to the Connection Technology series under FESTO company, model number MS12-AGI. To purchase or inquire about Base Kit MS12-AGI, you can directly contact 158 0047 0089 (Mr. He).