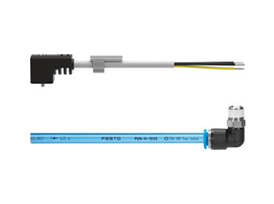

Basic Information of FESTO (Festo) L-type Quick-Connect Threaded Fittings QSLV - G3/8 - 8 - I

FESTO (Festo), a renowned company in the field of automation technology, produces the L-type Quick-Connect Threaded Fittings QSLV - G3/8 - 8 - I, which is a product of great interest. The model number 'QSLV' represents the series of the fitting, 'G3/8' specifies the thread size as G3/8, a common British pipe thread that can be well matched with many pipes or equipment of the same specification. '8' indicates the outer diameter of the fitting's connection pipe is 8mm, and the final 'I' may represent a specific version of the fitting or certain special performance characteristics.

This fitting采用 L-type design, which has significant advantages in practical applications. The L-type structure allows for connections in different directions, making the pipe layout more flexible. In situations with limited space or a need to change the direction of the pipe, the L-type Quick-Connect Threaded Fittings QSLV - G3/8 - 8 - I can easily adapt, greatly improving the convenience and efficiency of pipe installation.

Performance Characteristics of FESTO (Festo) L-type Quick-Connect Threaded Fittings QSLV - G3/8 - 8 - I

Firstly, the quick-connect method of connection is a major highlight. Traditional threaded connections often require tools for tightening, which are relatively cumbersome, and there is a risk of thread damage during installation and removal. QSLV - G3/8 - 8 - I采用 a quick-connect design, no tools are needed, just insert the pipe into the fitting to complete the connection, greatly saving installation time. At the same time, when removal is needed, the pipe can be easily pulled out, facilitating subsequent maintenance and replacement.

Secondly, the fitting has good sealing performance. During the manufacturing process, Festo采用 advanced sealing technology and high-quality sealing materials to ensure that the fitting can effectively prevent media leakage after connection. Whether in gas or liquid delivery systems, it can ensure the stable operation of the system, reducing energy waste and equipment damage caused by leakage.

Furthermore, QSLV - G3/8 - 8 - I has high durability. It采用 high-quality materials that can withstand certain pressure and temperature changes. Under normal usage conditions, the fitting can maintain good performance for a long time without easy damage or aging, reducing the user's cost of use.

Application Scenarios of FESTO (Festo) L-type Quick-Connect Threaded Fittings QSLV - G3/8 - 8 - I

In the field of industrial automation, this fitting has a wide range of applications. For example, in pneumatic control systems, it can be used to connect various pneumatic components, such as cylinders, solenoid valves, etc. Due to its quick-connect method of connection and good sealing performance, it can quickly build a stable pneumatic circuit, improving the response speed and

L-shaped Quick Connector with Thread QSLV-G3/8-8-I belongs to the Connection Technology series under FESTO company, model number QSLV-G3/8-8-I. To purchase or inquire about L-shaped Quick Connector with Thread QSLV-G3/8-8-I, you can directly contact 158 0047 0089 (Mr. He).