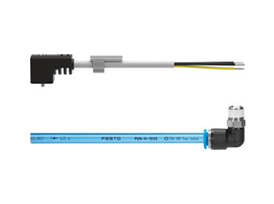

FESTO (Festo) Quick Connector KS3 - CK - 6 Introduction

FESTO (Festo), as a globally renowned supplier of automation technology, is known for the high quality, reliability, and innovation of its products. The Quick Connector KS3 - CK - 6 is a representative product from the Festo line. This quick connector is mainly used in pneumatic systems to achieve rapid connection and disconnection of pipelines, providing great convenience for users.

The design of KS3 - CK - 6 complies with ergonomic principles, featuring a compact and delicate shape that is easy to handle. In terms of materials, it uses high-quality engineering plastics and metal materials, ensuring the strength and durability of the connector while also offering excellent corrosion resistance, capable of adapting to various complex industrial environments. The sealing performance of the connector is also outstanding, effectively preventing gas leakage and ensuring the stable operation of the pneumatic system.

Features and Advantages of FESTO (Festo) Quick Connector KS3 - CK - 6

Firstly, quick connection is one of the core features of KS3 - CK - 6. The connector employs advanced quick connection technology, allowing connection or disconnection of pipelines to be completed in a short time with simple plugging and unplugging actions, greatly improving installation and maintenance efficiency. Compared to traditional connection methods, it saves a significant amount of time and labor costs, making it particularly suitable for situations that require frequent pipeline changes.

Secondly, KS3 - CK - 6 has good versatility. It can match various sizes of air hoses, adapting to different pneumatic system requirements. Whether in small experimental equipment or large industrial production lines, it can be put to use. This versatility makes it more flexible and convenient for users when choosing and using, reducing the troubles caused by size mismatches.

Furthermore, the safety of the connector is worth mentioning. It is equipped with a reliable locking device to ensure that the connector does not accidentally come off when connected, thereby preventing gas leakage and equipment failure due to pipeline disconnection. At the same time, the surface of the connector has been specially treated to have good anti-slip properties, allowing operators to handle it more safely and steadily during plugging and unplugging operations.

In addition, Festo has very strict quality control over its products. KS3 - CK - 6 has undergone rigorous testing and inspection, possessing high reliability and stability. During long-term use, it can maintain good performance, reducing the frequency of repairs and replacements, and lowering user costs.

Application Scenarios of FESTO (Festo) Quick Connector KS3 - CK - 6

In the field of industrial automation, KS3 - CK - 6 has a wide range of applications. For example, in automated production lines, pneumatic systems are extensively used in the driving and control of various mechanical equipment. The Quick Connector KS3 - CK - 6 can be used to connect pneumatic components such as cylinders and solenoid valves, achieving rapid transmission of gas...

Quick Connect Plug KS3-CK-6 belongs to the Connection Technology series under FESTO company, model number KS3-CK-6. To purchase or inquire about Quick Connect Plug KS3-CK-6, you can directly contact 158 0047 0089 (Mr. He).